USE OF ALKOXYSILANES FOR PROTECTION OF CROSS-LAMINATED TIMBER FROM FIRE IN BUILDING DESIGN

1 INTRODUCTION

1.1. BACKGROUND

Cross-laminated timber (CLT) mainly comprises more than three layers usually an odd number of timber panels sawn softwoods placed on top of each other at right angles and glued together resulting in an overall thickness of 50 to 500 mm. It is suitable for roof, floor and wall elements of length’s less than 13.5m (Technology, 2011). The use of cross-laminated timber in building design is gaining popularity throughout the world. It is being manufactured in a controlled manner in limited places like Europe and North America. According to a study conducted by Pei Shiling ,Popovski Marjan and Lindt John W. van de (2012), CLT has been seen to be effective in the design and construction of multi–storey buildings in high seismic regions. The test mainly comprised the performance-based seismic design of a 10 storey building CLT apartment that uses the ductile properties of CLT panel walls. CLT has also been used as floor systems that are supported by glue-laminated columns for the design of parking garages (P. & S., 2010). Developments with regards to CLT incorporation are still going on and one such scenario is use of CLT elements combined with concrete in the construction of tall buildings such as wood-concrete skyscrapers. Giudice, Carlos A., Alfieri Paula Vanesa and Canosa Guadalupe (2013) carried out a synthesis of polysiloxanes in wood pores by sol-gel process using aminopropyltriethoxysilane, aminopropylmethyldiethoxysilane and a 50/50 ratio mixture of both of them. Through a 2 foot tunnel test of the impregnated panels, it was discovered that aminopropyltriethoxysilane wood showed the best fire resistance. This because of better reaction with alkoxides to form a hybrid structure. Cross laminated timbers has better fire resistance capabilities in comparison to timber frames. Cross laminated can be designed to offer fire resistance and ability to maintain structural integrity in buildings when exposed to high temperature in comparison to steel (Greenspec, 2020). Cross laminated timber can be altered to offer fire resistance from 30 , 60 and 90 minutes only beyond which it is difficult.

1.1.1 PROBLEM STATEMENT

Though the design cross-laminated timber is being adopted across Europe places such as UK and United States have not fully adopted it due to barriers such as (1) systems integration (fire safety, acoustics, plumbing, electrical),(2) information gaps (3) Aesthetics (4)Skills shortage (5) Ban on combustible building materials The ban on the use of combustible building materials, legislation published by the Ministry of Housing, Communities and Local Government states that combustible materials will not be permitted to be used on external wall systems (Ministry of Housing, 2018). This will limit the use of CLT in building constructions since architectural and engineering design heavily relies on the cross-laminated timber to create a sustainable alternative to concrete and timber. The enforcement of the legislation was due to Grenfell Tower tragedy that was characterised by fire that was accelerated by the combustible cladding that accelerated the fire killing about 72 people. This will act as a problem for this research, in that ensuring claddings to be used are fire protected therefore making them fireproof in this case, cross laminated timber.

2 RESEARCH GOALS

2.1 OBJECTIVES

- To determine the best Alkoxysilanes to be impregnated in cross-laminated timber to provide fire protection

- To demonstrate how Alkoxysilanes can be used as protection for cross-laminated timber as a way of providing fire protection in building design.

- Demonstrate innovation tools in the innovative approach on use of sol-gel method as a fire protection on cross-laminated timber

2.2 RESEARCH QUESTIONS

- What are the best alkoxysilanes to be used to offer fire protection in building designs?

- Can CLT be protected from fire using sol-gel method?

- Do Alkoxysilanes used CLT protection have negative effects on the building occupants?

3 RESEARCH METHODOLOGY

To carry out the research an idea evaluation matrix was used to assess the following factors (1) Time (2) cost (3) potential impact (4) monetary impact. The matrix was to follow the following steps:

- Selection of the ideas to put through the matrix

This stage involved the selection of the innovation idea that would help provide fire protection to cross laminated timber in building design.

- Selection of ranking criteria

The next step was the building of a matrix to decide the criteria that would be used to score the innovation ideas. The criteria used in this innovation included; cost, toxicity, thermal behaviour and fire performance.

- Cost

A determination was done to determine how much it would cost to bring the idea to fruition.

- Toxicity

A determination on the toxicity of the alkoxides to be used would be checked to ensure the building occupants are not at risk.

- Thermal behaviour

The thermal behaviour of cross laminated timber in a fire outbreak scenario

- Fire performance

A determination of the performance level of alkoxides to be synthesised in cross laminated timber in the case of fire would be done

- Rating of the criteria

A rating scale was established that ranged from 1 to 4 with 1 being the point of the scale of low importance while 4 being the point with the highest importance. The ratings were added to the matrix below each criterion

- Score each idea

The next step involved the scoring of the idea based on the criteria chosen. The score ranged from 1 to 5 with 1 being the least effective and 4 being the most effective.

- Calculation of each idea’s weighted score

The calculation for each idea’s weighted score was done for each criteria. The calculation of the weighted score for each idea for the chosen criteria involved the multiplication of the ranking chosen for each criterion with the score given to a particular criterion.

- Summation of the weighted scores and comparison made

The final step involved the summation of the weighted scores across each criterion for the ideas chosen in the matrix and the final score written in the last column. A comparison of the scores would be done to evaluate the most viable based on the highest score.

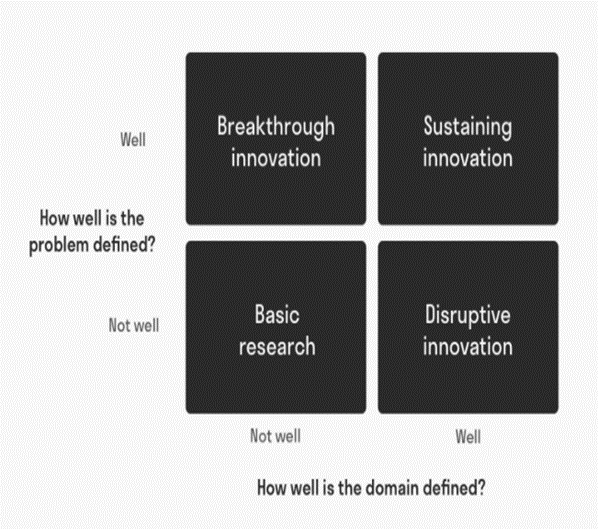

The next step was the use an innovation matrix to visualize the various aspects of innovation of ways CLT can be protected from fire and make a determination and conclusion of the type of innovation. The innovation matrix focused on four types of innovation that include: Breakthrough innovation, sustaining innovation, basic research and disruptive innovation. The innovation matrix to be used is demonstrated below:

Figure 1‑1showing innovation matrix.

4 ANALYSIS

4.1.1 IDEA EVALUATION MATRIX

Table 1showing innovation matrix

| IDEA | Cost | Toxicity | Thermal Behaviour | Fire Performance | Total |

| Coefficient | 1 | 2 | 3 | 4 | |

| 1. Synthesis of aminopropyltriethoxysilane in Cross Laminated Timber by sol gel process | 4 | 3 | 2 | 2 | |

| Weight rating | 1 x 4 = 4 | 2 x 3= 6 | 3 x 2 = 6 | 4 x 2 = 8 | 24 |

| 2. Synthesis of aminopropylmethyldiethoxysilane Cross Laminated Timber by sol gel process | 3 | 3 | 4 | 4 | |

| Weight rating | 1 x 3 = 3 | 2 x 3 = 6 | 3 x 4 = 12 | 4 x 4 = 16 | 37 |

| 3. Synthesis of 50:50 ratio of mixture of both aminopropyltriethoxysilane in Cross Laminated Timber by sol gel process | 2 | 3 | 3 | 3 | |

| Weight rating | 1 x 2 = 2 | 2 x 3 = 6 | 3 x 3 = 9 | 4 x 3 = 12 | 29 |

5 DISCUSSION

For this innovation three different ideas were adopted for the use of alkoxysilanes in Cross Laminated Timber for building design as a means of providing fire protection. The ideas adopted included the synthesis of aminopropyltriethoxysilane in Cross Laminated Timber by sol gel process, synthesis of aminopropylmethyldiethoxysilane in Cross Laminated Timber by sol gel process and synthesis of 50:50 ratio of mixture of both aminopropyltriethoxysilane and aminopropylmethyldiethoxysilane in Cross Laminated Timber by sol gel process. The criteria to be used included the following;

- Cost

- Toxicity

- Thermal Behaviour

- Fire performance

For fire performance the score ranged from 2 to 4 for each idea adopted as per the criteria coefficient of 4. The score of each ideas was based on a study by Giudice, Carlos A., Alfieri Paula Vanesa and Canosa Guadalupe (2016) on the performance of wood impregnated with alkoxysilanes in terms of determination of performance against fire. The impregnation process with alkoxysilanes was done in a 45°C to 50°C autoclave controlling the operations in order to achieve different weight gains. In the study tests were carried out in a Two-Foot Tunnel in accordance to ASTM D 3806 Standard. Three wood panels with different samples were used that comprised the following: aminopropyltriethoxysilane synthesised wood, aminopropylmethyldiethoxysilane synthesised wood and a wood synthesis of 50:50 ratio of mixture of both aminopropyltriethoxysilane and aminopropylmethyldiethoxysilane. The wood specimens used were specifically Araucaria angustifolia. A global analysis showed that there was an improved performance of wood treated with alkoxysilanes in comparison to the control panel. According to the study wood samples that were impregnated with aminopropylmethyldiethoxysilane showed best performance in terms of the weight gained during the reaction with fire therefore improving its dimensional stability. The wood samples impregnated with 50:50 mixture of aminopropyltriethoxysilane and aminopropylmethyldiethoxysilane showed the second best average results in terms of weight during the fire reaction and the wood treated with aminopropyltriethoxysilane showed the least weight gained. Therefore using the results of this study, a similar idea was envisioned for cross laminated timber impregnated with the alkoxysilanes. It was assumed that since the cross laminated timber is a wood product it would show a similar pattern of results. Therefore Idea 2 would assume the best score of 16 in terms of fire performance, followed by idea 3 and ideas 1 in that sequential order.

For Toxicity criterion all ideas had a similar score of 6. According to Evonik Industries (n.d.) Aminopropyltriethoxysilane is not toxic if inhaled or exposed to the skin but may prove harmful if swallowed. It is also not harmful after repeated exposure. In this case where the Cross Laminated Timber is impregnated with Aminopropyltriethoxysilane it is assumed during a fire outbreak in a particular building the occupants may not be exposed to toxic inhalation or dermal reaction. There is also little likelihood of the occupants ingesting the toxins. Therefore the idea 1 is given a score of 3 due its small degree of toxicity. The same applies to aminopropylmethyldiethoxysilane which is considered toxic when swallowed hence a similar score. Therefore an assumption is made a 50:50 mixture would exhibit the same properties and hence a score of 3 is applied in the matrix.

In terms of cost, according to Merck (n.d.)100ml of Aminopropyltriethoxysilane price is 91.70 Euros and 500 ml price is 317.00 Euro. The price of Aminopropylmethyldiethoxysilane is 50.50 Euros for 50ml and 187.00 Euros for 250ml (Merck, n.d.). Therefore the score of 4 and 3 were applied to idea 1 and 2 respectively on the idea evaluation matrix. A mixture of both alkoxysilanes would prove to more expensive hence the score of 2 in the idea evaluation matrix.

In terms thermal behaviour the score ranged between 2 and 4 for each idea adopted as per the criteria coefficient of 3. The score for each idea was also based on a study by Giudice Carlos A., Alfieri Paula Vanesa and Canosa Guadalupe (2013) where thermal behaviour of wood panels impregnated with alkoxides after formation of gel and in –situ aging were tested in a Shimadzu TGA -50 H detector. A control wood sample was treated with sodium hydroxide solution. For the minimum weight gained for the three wood samples impregnated there was no major difference in terms of initial temperature of decomposition in comparison to control sample. It was however noted during the reaction as the weight increased fast thermal decomposition was lower. The wood treated with aminopropylmethyldiethoxysilane had the best performance in terms of thermal decomposition. The thermal performance of wood treated with 50:50 mixture of aminopropyltriethoxysilane and aminopropylmethyldiethoxysilane showed the second best results and lastly the wood treated with aminopropylmethyldiethoxysilane showed the fastest thermal decomposition hence least results. Therefore using the results of this study, a similar idea was envisioned for cross laminated timber impregnated with the alkoxysilanes since cross laminated timber is a wood product. Therefore similar results are expected to be seen in case of thermal decomposition in case of fire outbreak in a building. Therefore Ideas 2 in the idea evaluation matrix would assume the best score of 16 in terms of fire performance, followed by idea 3 and ideas 1 in that sequential order.

From the idea evaluation matrix it is evident that the innovative idea of synthesis of aminopropylmethyldiethoxysilane cross laminated timber by sol gel process to offer fire protection has the best score of 37 therefore it is the most preferred idea to be adopted.

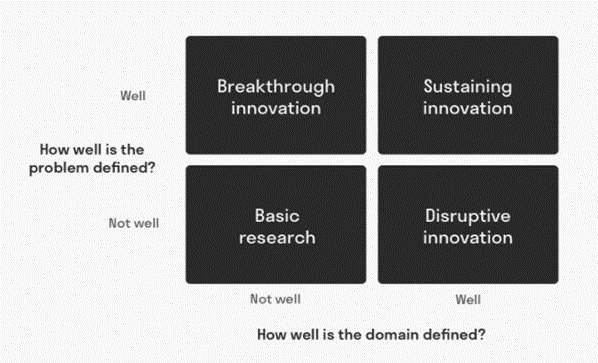

Using the innovation matrix below the innovation can be termed as sustainable innovation since the problem has been well defined and domain clearly defined. There is a clear understanding of the problem which involves the fire protection of cross laminated timber used in building design and solution for it through the impregnation of aminopropylmethyldiethoxysilane in cross laminated timber.

Figure 1‑2 showing innovation matrix to be adopted

6 CONCLUSION

The study was a success since the determination of the best Alkoxysilanes to be impregnated in cross-laminated timber to provide fire protection which in this case is aminopropylmethyldiethoxysilane. It was possible to point out that cross laminated timber can be protected from fire using sol-gel method. This was made possible through the use of previous literature on the impregnation of alkoxysilanes on wood with success. Demonstration of innovation tools in the innovative approach to use of sol-gel method as a fire protection on cross-laminated timber was done using idea evaluation matrix that was able to point out the best idea to adopt. Also the use of an innovation allowed for the clear understanding of the type of innovation that has been made. It is also clear that use of aminopropylmethyldiethoxysilane as fire protection does not pose any pollution or toxicity to the building occupants in case of fire.

Peachy Essay essay services team offers a wide range of services including Engineering Writing Help:

– General Engineering Assignment Writing Services

– General Engineering Essay Writing Service

– General Engineering Dissertation Writing Service