INTRODUCTION

Every modern business organization has an operation function. In simply put, what the company does to be in existence. A typical company has several operations starting from the receipt of raw materials, production, to distribution of finished products to the customers. To facilitate all these operations, there must be a well-defined layout of activities that are followed and monitored for their effectiveness. This comes under the responsibility of operations management. Operations management encompasses all functional areas that play a part in managing the operations that lead to the production of goods and services needed by the customers. Operations management can mark that difference between success and failure of any given organization depending on how effective it is conducted.

A flawless operations management would translate to reduced costs, increased efficiency, and high customer satisfaction. On the other hand, a problematic operations management can severely affect the performance of the company leading to unprecedented losses and unsustainability. In the recent past, operations management has become an integral part of the strategic organizational management. Strategic operation management integrates various decision-making tools into the organization’s strategic goals that aim at increasing competitiveness.

The aim of operations management is to make optimal use of the resource that an organization has to provide finished goods and services required in the market in a timely and cost-effective manner. This report seeks to analyze operations that play a vital role in the overall success of an organization. The focus of the report is on restaurant business that has a global recognition; the McDonalds. The report examines the operation of managing stock, production to the sale of final products that meet the customer needs. Moreover, it relates the operations management activities with the overall strategy of the company.

Company Overview

McDonalds is one of the leading hamburger fast food restaurants in the world with hundreds of branches all over the world. In the United Kingdom, the company has several restaurants spread across the country. One of them is McDonald’s Waterloo Station, which is the basis of analysis of this report. The company’s history dates back in 1940 when it was first launched by the McDonalds brothers Dick and Maurice in San Bernardino, California, United States. Over the years, the restaurant chain has consolidated its position in the fast food business with a presence in over 120 countries and serving close to 50 million customers each day.

Figure 1: McDonald’s Restaurant at Waterloo Main Station

The company has taken effective measures in the past towards ensuring that its customers, business partners, suppliers and the general public enjoy quality services and products. Currently, McDonalds is developing a sustainable and reliable supply chain on behalf of its suppliers and distributors to ensure that the business flows uninterrupted. In all its restaurants across the globe, the majority of the key operations are linked to the overall strategy of the organization. Some of these operations include; product planning, process planning, managing stock, and quality management. As already mentioned above, this report focuses on the managing stock to meet the customer needs. This directly falls under the inventory management. Inventory management is a critical operation of McDonald’s because it is what makes the restaurant meet the expected demand for the products. How well the business manages stock determines the volume of sales the restaurant makes on any given working day and hence the overall profitability.

DISCUSSION

Critical Evaluation of the McDonald’s Performance Objectives

McDonald’s has set its performance objectives in a way that they help the business maintain its position as the global leader of fast food business. To meet its objectives the restaurant is divided into various departments each with a specific function to play in the process of meeting the set goals. There are several key performance objectives which the restaurant rely on ensuring that it meets the daily needs of its customers.

Speed

Speed refers to the time taken for a response to be obtained. Speed is important because it helps to respond quickly to customers thereby enabling them obtained the service or product they ordered. The speed of serving customers can determine whether or not they will return to the business again. Over the years, McDonald’s has perfected the ‘drive-thru’ policy where it only takes 90 seconds for a product to be served to the customer either on the restaurant table or over the counter if the purchase is a ‘take way.’ It is the speed of service delivery that makes McDonald’s to be the leading fast food restaurant in the city. This is in line with the company’s strategy of customer satisfaction through the speed of response.

Cost

Cost reduction is one of the major objectives of the restaurant. McDonald’s is a master when it comes to reducing the cost of operations in the business. The fast food market is a highly competitive market that price wars are very common. In order to stay in the business, the restaurant has put in more effort in reducing the cost of production so that it sells the products at the lower prices but still make profits. Cost leadership is working for the restaurant because it has seen its main competitors making heavy losses under the normal market prices. McDonald’s is using the cost leadership to gain a competitive advantage in markets it operates. Cost reduction come as a result of increased automation, improved employee productivity as well as having reliable suppliers.

Quality

McDonald’s operational policy puts quality first in its list of performance objectives. Quality refers to the conformance of a product or service to its specifications. The restaurant works on a belief that the customers deserve the best quality of a product so that they have less to complain about. If customers have nothing to complain about then, they will definitely be happy. A happy customer is likely to consume a product again. This in turn brings more revenue to the restaurant. Regarding operations, the restaurant ensures that the quality of processes and activities is all time high and hence not room for mistakes. The assumption here is that mistakes compromise the quality of a product as well as increasing the cost of production. Therefore, the restaurant cannot allow them to happen.

Flexibility

In the context of McDonald’s business model, flexibility means the ability to change an operation in a certain way. In McDonald’s restaurant, flexibility takes three forms. The first one is mix flexibility where an operation produces a wide variety of products from which the customers can choose from. The second is the product/service flexibility. Here, the restaurant comes up with new ideas that are incorporated into the making of a food product or services that customers find attractive. The third type is the volume flexibility the restaurant adjusts its output levels in order to cope up with the unexpected changes in demand. All forms of flexibility are undertaken independently. In is important to note that flexibility at McDonald’s increases the speed of service delivery thereby saving time and money.

Dependability

Dependability refers to the act of customers receiving their products or services on time. In the fast food business, dependability is always an added advantage to the business operations because customers don’t like to be inconvenienced. Some of them are usually under a time constraint and, therefore, delaying a plate of food can cause considerable irritation. Dependability directly affects the volumes of sales because customers always return to the restaurant knowing that the food or drink will be delivered to them quickly and hence have no much time to waste.

Customer Expectations and Perceptions of Quality

Customer expectations and perceptions about the quality of products sold to them determine the level of their satisfaction. For a customer to walk in a McDonald’s restaurant, s/he expects that the quality of the products is offered for sale is undoubtedly exceptional. McDonald’s enjoys unrivaled customer loyalty in the fast food market due to the high-quality products that they sell. For instance, the hygiene standards in the restaurant and kitchen are so high that a customer creates a perception that such standards and processes ensure that the food is high quality. The restaurant quality assurance managers and supervisors conduct routine quality checks thereby eliminating any possibility of poorly prepared foods or drinks. Also, the customers are likely to determine quality by evaluating the nature of services accompanied by product.

Figure 2: McDonald’s Bacon Clubhouse Burger

The company understands the fact that its business depends on the customer expectations and perceptions of quality regard the products offered and their related services. This explains why the restaurant has in the recent past continued to provide innovative products that are aimed at improving the dining experience for its customers. Quality enhancement is also being achieved by the periodic restaurant imaging where the management wants diners to have a modern and inviting atmosphere even as they enjoy their food or drinks. As such, the restaurant has been refurbished both in the interior and exterior thereby creating a new image of high quality. All these activities have made McDonald’s restaurant high visible and among the first on the list when a customer thinks of fast food restaurants in the UK.

Quality Management in the McDonald’s UK

Whether profit or non-profit organization, quality management is one single critical undertaking that ensures that only the best products and services are provided to the users. It helps in the strengthening of the reputation of the organization even in the midst of stiff competition. Quality at McDonald’s restaurant is an essential part of the business because of two reasons. Firstly, there are legal requirements in the UK controlling the quality of food to be served to the public. Secondly, McDonald’s strives to maintain the hard-earned reputation it has enjoyed for decades. The McDonald’s restaurant carries out some routine quality assurance checks such as ensuring highest standards of hygiene are observed within and outside the restaurant. All employees are required to be in their clean official dressing before embarking on their daily activities[10]. Some of the quality assurance practices are also used such as regularly inviting food inspectors and public health officers to conduct quality checks. The restaurant has employed several supervisors who main role is to oversee various processes and activities to ensure that quality is not compromised in any way.

Quality management at McDonald’s has been enhanced with the introduction of the just-in-time (JIT) system of operation. This means that the restaurant does not begin to cook until a customer places a specific order. It is no longer the case of pre-cooking say hamburgers only to place them under heat lamps waiting for customers to order . That is a normal practice in some of the fast food outlets but not at any McDonald’s restaurant. The JIT system has been beneficial to McDonald’s not only in managing the quality of food and drinks but also at lowering costs because wastages are accumulated.

The Supply Chain of McDonald’s UK

While meeting the daily needs of its customers, the McDonald’s struggles with keeping the prices of its products low so that an average person can afford a meal in its restaurants. The customer needs have been changing with time, and therefore, it forces the restaurant to cope up with the change avoid losing out competitors. The supply chain of the McDonald is guided by the four ideals of the company that includes quality, hygiene, services, and value to the customer.

Structure of the Supply Chain

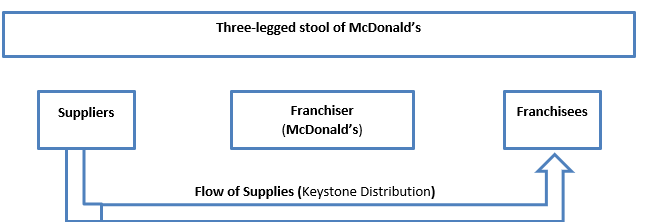

The entire McDonald’s is a franchise business. This implies that the company normally enters into a rental agreement with the potential investors. The investors who want to be franchisees rent the restaurant building from McDonald’s and then transacting business using the McDonald’s brand name. This business model adopted by McDonald’s is referred to as three-legged stool. As shown in the flow chart below, the stool consists of suppliers, McDonalds and the franchisees with each representing one leg. The logistics company known as Keystone Distribution facilitates the flow of supplies within this three-legged system. Over the years, the company has eliminated several bottlenecks that used to hinder the delivery of supplies on time and in required condition.

Logistics Service Providers

Like many other companies in the UK, McDonald’s does not handle its own logistics-related operations. It has entered into an agreement with another company to concentrate on its core operation. One advantage of this arrangement is that McDonald’s enjoy the efficient and specialized service without worrying about the transport related costs and staffing. As mentioned earlier, the company that runs logistical operations on behalf of McDonald’s is Keystone Distribution UK, which is a subsidiary of the Keystone Foods LLC. The two companies entered into a partnership in 1977 where the main logistics operation was transporting hamburger bun. Today, Keystone efficiently transports everything from suppliers to the franchisees. Thus, Keystone plays an integral part in the supply-related operations for McDonald’s so that its 1200 stores in the UK can run their individual businesses successfully.

Figure 3: Keystone Distributor on Transit

Undoubtedly, a large organization like McDonald’s requires a third-party company to handle its warehousing and distribution of its fresh and frozen foods and raw materials so that it focuses on the core operations. However, there is also a danger in outsourcing logistics activities especially from one provider due to the possibility of losing control over logistical operations. This explains why various McDonald’s restaurants including the one at Waterloo Station have a high dependency on the Keystone Distribution such that business operations are disrupted in the instance that the provider has problems.

Suppliers

McDonald’s restaurant deals with different suppliers from all over the country thereby enabling the business to provide a wide variety of products at affordable prices. For instance, the Sun Valley and Moy Park companies supply McDonald’s with chicken products, Ecsa supplies beef products. There are also small-scale suppliers who provide supplies to the restaurant directly without the services of Keystone Distributor. This has been advantageous to the company because the suppliers deliver products on time and at no extra costs[13]. Additionally, there is room for adjustments should one supplier fails to deliver the expected products on time or in the rightful quality and quantities. However, there are also demerits of managing this complex network of the supply chain. One is that there is heavy investment of resources, time, and money to ensure that every operation in the supply chain goes as planned and efficiently.

Stock Control at McDonald’s

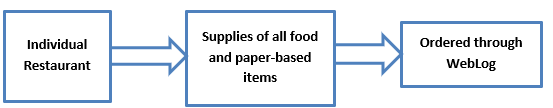

The processes involved in making sure that there is enough stock at all times to meet the prevailing customer demands can mark the difference between profit and loss in the fast food business. Moreover, the cost of holding too much stock is always high given the fact that much of the stock is composed of perishable products. McDonald’s has avoided such costs by use of the inventory control system known as Manugistics. With this system in place, the restaurant can keep a small buffer stock just in case demand increases or a temporary delay in a shortage of stock is experienced[14]. One advantage of Manugistics is that it can help in forecasting demand using historical data relating to school holidays, upcoming events as well as new promotions. The inventory manager uses a simple web-based communication platform known as the WebLog.

With this web tool, the manager can view the stock deficiencies and order for more stock. On a daily basis, the WebLog creates orders that are analyzed by the managers before a proposal is sent out to the central planners who give the final decision on whether the stock in question should be delivered.

It is no doubt that McDonald’s restaurant has been facing stiff competition from other fast food businesses and hence forced to expand its range of menu. The menu is normally divided into two categories, that is, for those customers who know what the menu contains and those that are new to it. When a customer walks into the McDonald’s restaurant, the first stop is the counter where an order is placed. The till attendants apply two techniques in serving the customer either selling or suggesting technique. Selling technique is where the customer is asked whether s/he would like a large portion for a reduced price. On the other hand, the suggesting technique is where the customer is asked to spend a certain amount to get an extra item. A till attendant is expected to complete order within a minute of the standard service time. There is a standard sequence of serving the customer either over the counter or on the table. Cold drinks are normally the first followed by hot drinks, then fries and lastly burgers. The orders are processed on the first come first serve basis implying that the first customer on the queue is served first, followed by the second, and continues in that pattern.

CONCLUSION

McDonald’s successes over the years have come as a result of persistent and consistent improvement of its operations management activities and processes. Although the company has faced a myriad of challenges including stiff competition and tough economic times, it has employed various strategies to counter the problems. The McDonald’s restaurants continue to improve in operational efficiency thereby proving quality products that beyond customer expectations. Also, the company has an effective and well-integrated supply chain consisting of reputable suppliers and franchisees that follow the ideals of McDonald’s ranging from quality, cleanliness, and value to the customer. All these factors combined, McDonald’s can still stay ahead of the competitors in providing quality healthy products and at affordable prices. However, the restaurants need to minimize the cost of monitoring the supply chain because it is taking many resources in terms of time and money.

Recommendations

Establish joint planning

McDonald’s spends a lot of resources on operations relating to supply chain. Given the fact that Keystone Distribution is the link between the suppliers and franchisees, the company should institute a joint planning between the distributor and these other parties, so that cost of monitoring these activities reduces. This kind of arrangement ensures that the company does little in facilitating the flow of the supplies from the suppliers to the franchisees. This will be cost-effective in the long-run as suppliers will understand the sales forecast and standard procedures required for competitive business.

Design innovate food items

Since the largest composition of the McDonald’s customers is young people, the company should invest in promotional activities that are more appealing to the youth. One of the reasons is that young people have changing tastes and preferences, and, therefore, they would only consume items that they consider trendy. However, key attention must be given to the prices because if those new products are sold at high prices, the customers would rather buy from the competitors.

Here are some of our outstanding business services:

– Business Essay Writing Service

– Business Dissertation Writing Services

– Business Report Writing

– Business Assignment Help

– Business Planning Writing Service

– Business Assignment Writing Service