Analysis of Toyota Total Quality Management Approach

The ever-competitive nature of business has always been at the core of company stakeholders working hard daily to improve the quality and processes involved in producing their products or services. Companies have to prioritize customer satisfaction, which in return calls for customer loyalty, which pushes the company revenue up. The organization’s most common strategy is the adoption of the total quality management technique in their production process. TQM focuses on the customer, employee, the process, and the harmonious integration of the listed elements. Thus, total quality management is defined as an approach in management focused on the long-term excellence of a company by emphasizing its customers’ satisfaction. This paper thus presents an analysis of the TQM approach and its implementation at Toyota Motor Corporation TMC.

The Application of Total Quality Management Approach at TMC

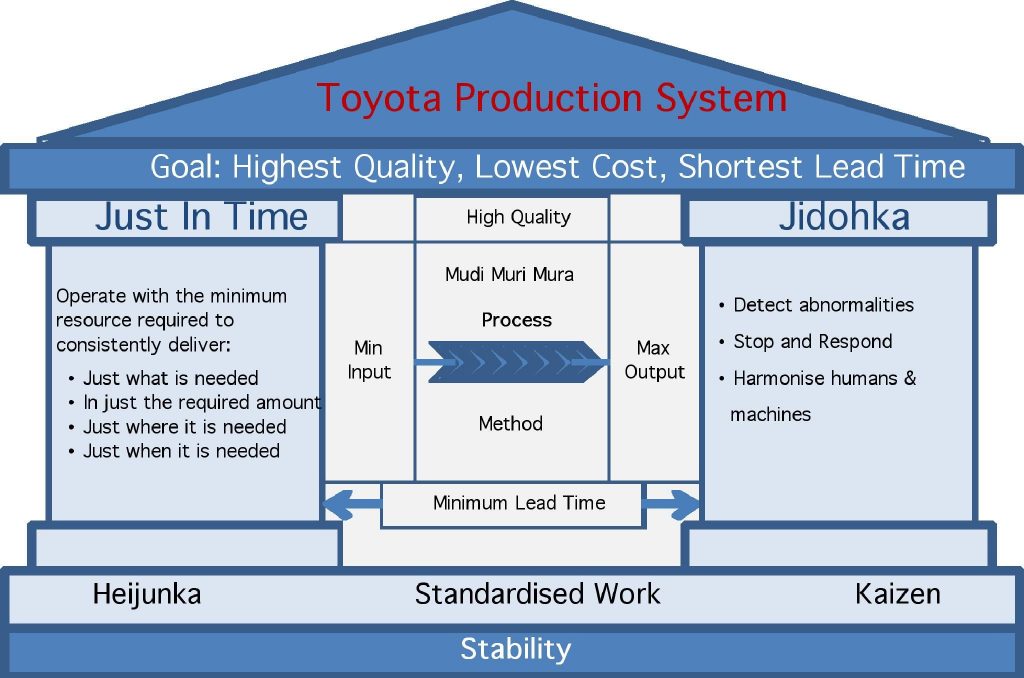

Toyota Motor Corporation has been the leading car seller globally for a long time; the company’s achievements are pegged to its system of attaining business excellence. TM Cavoids waste in its line production by using just-in-time techniques and focusing on manufacturing the best quality products at a lower cost within a short lead time (Sorin-George & Shinji, 2017). However, the company’s business excellence is attributed to its use of the TQM approach. Below are some of the company’s notable applications of total quality management and its contribution to business excellence.

Focusing on customers

Toyota Motor Corporation has been able to achieve its current levels of business excellence by focusing on customers. The company believes that its wellbeing depends on the level of customer satisfaction attained from its products. As a result, the company notably has customer feedback centers across the world to get to learn about what the customer needs. The company has thus been able to build products addressing customers’ needs, which builds customer loyalty; an example is some of its cars for people with disabilities.

Strong Leadership

The company leaders have contributed to the company’s business excellence and ensuring that the manufacturing processes taking place at the company are intended to satisfy the needs of all stakeholders, including the community. More importantly, a strong leadership base contributes significantly to implementing the principles under Total Quality Management. The leaders’ obsession with being the best has also contributed to its excellence by focusing on producing quality products that also lead to better revenue (Kumar et al., 2016). Which also helps grow its market share.

Improving Continuously

Through the principles set out in the Total Quality Management approach, Toyota Motor Corporation’s focus has been on attaining business excellence. As a result, the company’s set-used-always focused on an integrated effort to improve their production efficiency by addressing any inefficiencies along the production line. The company strives for quality in its production system, both to the visible and invisible parts. Hence, the employees are always up to learn and improve constantly, even to the smallest portions.

Workers focus

Toyota Motor Corporation TMC practices of workers focus projects some relationship with the Total Management Quality and business excellence. The company workers’ set upset upgrades the company’s production system that is automated and the human system. The company appreciates the contribution of human employees in the implementation of the production system. Thus, a family-like relationship co-exists among employees and between the employees and management.

Constant Learning

Another practice observed at Toyota Motor Corporation is the culture of lifelong learning since the periods before the war. The company has always been at the forefront in identifying the best available methods and then adopting and implementing them as part of the company’s production methods. Company executives have also been always on the move to scout competitors and learning from them. That is evident with some of the famous visits to Europe and America’s manufacturers made by TMC executives on a benchmarking mission.

Making Decisions Based on Facts

One of the core importance of Total Quality Management is that it emphasizes all aspects of production, and one of them is decision making. To produce satisfactory products from the consumer’s perspective, the company applies a decision-making approach that relies on facts(Sorin-George & Shinji, 2017).Through the problem identification process, the root cause of concern spotted. Thereafter, the parties in charge make sound decisions to handle the problem that is based on facts. That ensures that the result is an outcome that results in the production of the best quality products to meet the needs and demands of customers.

A close look at the case study involving Toyota Motor Company and how it applies Total Quality Management in attaining Business Excellence has some factors that are consistent with the text from the reading. The text defines Total Quality Management TQM with much emphasis on customer satisfaction as the key contributor to its long-term success. Among the familiar trend seen in the case study that is comparable to the text is Toyota Motor Corporation’s emphasis on customer satisfaction. Almost all of its Total Quality Management approaches are directed towards achieving business excellence by ensuring the production of top-quality products that meet customers’ needs. That explains how important customer satisfaction is to the excellence of any business.