The key to real customer value is effective supply chain management

Introduction

Creating and maintaining customer value is the most important objective of supply chain management. Firms have been experimenting in the last three decades to ensure that they provide customer-centric products and services to their clients within the shortest time possible. They have understood that customer satisfaction and loyalty are the major drivers of organizational success. Businesses have also realized that customer value does not include adding tangible benefits or extra to the products and services. The process comprises many factors such as meeting customer expectations, affordable prices, variety of products and services, tangible and intangible value addition, and relationship and experiences. Samsung, Zara, Walmart, Amazon, and Peapod have successfully used effective supply chain management, which explains their success in their core sectors. The activities of these firms have confirmed that the key to real customer value is effective supply chain management

Ability to Respond to Customer Requirements

Understanding customers’ needs is the most influential factor in improving supply chain management. According to Myerson (2015), the real value of a supply chain is the current and future customer needs. All firms must understand these desires and customize the entire logistics network according to them. Chavez, Yu, Jacobs, and Feng (2017) claim that companies are collecting a lot of data about their clients and other market features to remain competitive. The information provides important insights such as customers’ tastes and preferences, purchasing patterns, budget for the products and services, as well as the delivery methods chosen. Determining these factors has become extremely easy with the inception and acceptance of online shopping. Sanders (2014) further states that companies can track other things customers look at, the way they navigate the websites, and the way they are affected by the promotions. Thus, collecting data about clients is an important step in improving supply chain efficiency.

Clients today have more and complex demands that require firms to change the manufacturing process to alter quality. In some cases, consumers require the products sooner, which forces firms to use other methods to achieve that objective. Stevenson and Spring (2007) claim that the flexibility of supply chain is much more important compared to a manufacturing one. Moreover, moving the products from the firm to the consumers seamlessly is the primary objective of the logistics network. The inter-organizational relationship among all supply chain actors has precedence over all other issues. The connection allows firms to move altered products faster to the client, which is important in maintaining loyalty and satisfaction as well as enhancing firm performance (Sa´nchez & Pe´rez, 2005).

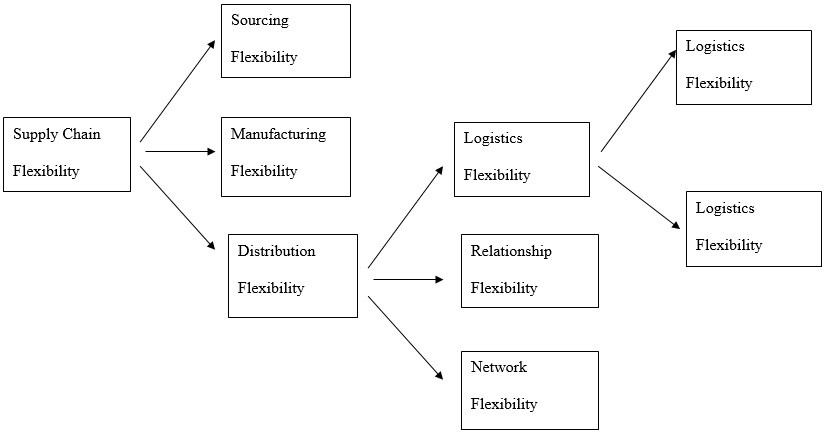

Supply chain flexibility comprises various aspects. According to Grigore (2007), firms must be alert to understand the changes they need to make whenever an issue arises in the supply chain. The first consideration is functional flexibility that may include changes to specific departments such as marketing, operation, or logistics (Grigore, 2007) while the second one is hierarchical that may include modifications at the shop, plant, or company level. Other aspects may include strategic, time, and requirement aspects. Whenever clients make demands, a firm must review the expectations to determine the departments and levels to alter and the turnaround period. Therefore, companies must be flexible enough to make changes to address customer needs fast.

Fig. 1. Diagram showing a supply chain flexibility framework.

Samsung electronics works hard to respond to customer needs as soon as possible. The firm claims that its main objective is to maximize customer value among other objectives (Samsung Electronics, 2017). Samsung ensures that it addresses the expectations in various ways. The first strategy has been developing high-quality products that can guarantee the customer’s health and safety. The firm has collaborated with more than 1,000 suppliers to ensure that the products it develops to meet the expectations (Lee, Lee, & Heo, 2015). In addition, it maintains a good relationship with all stakeholders to move products fast through the network. Consequently, it has reduced manufacturing and lead times while maintaining quality. Therefore, Samsung Electronics has an elaborate supplier relationship that improves its quest to address customer needs.

Samsung collects customer data to respond to their unique needs. According to the firm’s management, all Samsung staffs are required to conduct in-depth consumer analysis through studying their needs, lifestyles, and any behavioral changes. They collect the data by contacting the clients and asking questions related to products designs, services, and distribution channels (Samsung Electronics, 2017). The information collected allows the firm to customize its products and services to reflect the expectations. Samsung employs the strategic supplier system to manufacture and avail gadgets to the market as quickly as possible. The approach is successful since the firm provides details of the materials required, the schedule, and quantities of the products and their description three months in advance (Lee, Lee, & Heo, 2015).

Samsung uses a flexible supply chain that allows it to respond to consumer needs and complaints fast. The firm received complaints about poor services from its female clientele in the Middle East. In response, the firm conducted a two-month pilot study in Qatar to evaluate the suitability of having female engineers serve female clients (Samsung Electronics, 2017). The female participants were very satisfied with the model, which encouraged the firm to introduce similar services to Dubai in the United Arab Emirates, and Amman in Jordan (Samsung Electronics, 2017). Therefore, the flexible supply chain management at Samsung has led to the introduction of the successful ‘lady service’ project in the Middle East.

Samsung has an intensive supplier selection process to ensure it provides defect-free gadgets. The selected suppliers must be trained well to understand the expectations of the company. Thereafter, the firm determines their suitability by evaluating their procedures and management practices. Successful suppliers are officially provided with the Supplier Quality Control Innovation (SQCI) certification (Samsung Electronics, 2017). Samsung usually follows up with the supplier by conducting periodical quality checks. The approach has made it possible for Samsung to guarantee quality products according to customer expectations.

Low prices

Providing high-quality products at a lower cost is the hallmark of effective supply chain management. Madhani (2012) asserts that cost efficiency in the supply chain comprises providing products at lower prices while enhancing revenues. Achieving the objective requires firms to manage upstream order processing functions and the downstream demand and customer management (Madhani, 2012). The supply chain cost constitutes about 55% of the final product expense, which dictates the price the consumers pay (Lapinskaitė & Kuckailytė, 2014). It is important to maintain the perfect balance in addressing customer needs, enhancing inventories, improving sales and development opportunities, and maintaining good relations with the customers.

Companies must optimize inventories according to customer demands. According to Christopher and Gattorna (2005), firms must align their strategies and capabilities with market needs. Therefore, they need to understand the buying patterns and behaviors of the clients to align their manufacturing and marketing strategies. The common scenarios include mostly predictable, predictable, unpredictable, and very unpredictable (Christopher & Gattorna, 2005). These situations necessitate a multi-disciplinary approach to ensure that the firm caters for all clients. The alignment may force businesses to combine agile, lean, fully flexible, and continuous replenishment supply chain strategies (Christopher & Gattorna, 2005). The major objectives include customer, demand, manufacturing, and supplier management as well as order fulfillment and product development commercialization (Wisner, Tan, & Leong, 2018).

Exploiting sales and development opportunities are effective low-cost strategies. Companies today focus on controlling supplies, increasing inventory utilization, and reducing production, advertising, and research and development expenses. In addition, they work hard to increase sales to gain economies of scale (Nel & Badenhorst-Weiss, 2011). All supply chain decisions made must reflect market demands and expectations. The most influential factor is maintaining a balance between demand and supply. The companies must ensure that there is no oversupply or undersupply of the products and services. The former may increase storage costs as well as risks associated with the process. On the other hand, the latter may lead to loss of customers through switching brands or stores. In some cases, some customers may delay purchases awaiting their preferred firms to avail them (Madhani, 2012).

Zara has successfully optimized its supply chain to offer low-cost products to its clientele. The strategy includes setting targets for all the products, which is usually 15% lower compared to the major rivals (Aftab, Yuanjian, Kabir, & Barua, 2018). Reviewing and setting prices is the responsibility of the purchasing department, which does an extensive analysis of the other products in the market. The department controls the price of the materials to achieve the desired low cost to maintain the excepted price of the products. The firm produces more than 50% of the materials used to maintain control. In addition, it orders plain materials from the various suppliers to maximize its use by controlling the cuts, colors, and designs according to the customer feedback (Aftab, Yuanjian, Kabir, & Barua, 2018). Zara also exerts control of the products by doing most of the designs. It has a large design hall divided into men, women, and children segments in its headquarters in La Coruna headquarters. Each line has a dedicated procurement, production planning, design, and sales staff to ensure effectiveness. The strategy Zara uses helps it to be flexible in design, variety, and quantities, which is the reason it is able to sell most of its products (Aftab, Yuanjian, Kabir, & Barua, 2018). In addition, it can complete the entire supply chain process in just three weeks compared to 5 months by competitors. Consequently, it has been able to have twelve production turns per year compared to the maximum four by the competitors (Aftab, Yuanjian, Kabir, & Barua, 2018).

Chart 1. Comparison between Zara and competitors

Production Selection

Product and service variety is an important aspect of the supply chain. According to Ahmed, Uddin, and Ahshanullah (2009), variety differs based on the social values, constraints, and usage scenarios. In some cases, they may perceive variety as differences in similar products or variations of the same product through color, contents, and other physical attributes. Sun (2012) claims that it is important for firms to differentiate products and services to have a competitive edge today. However, creating new products and services should depend on the tastes and preferences of the clients as well as the perceived benefits of the products (ElMaraghy et al., 2013). Therefore, businesses must analyze the market continually to determine the new products and services customers want.

Differentiating products must meet the five levels. The first level is the actual benefit the customer is buying. The second aspect comprises the features of the product such as brand, packaging, and color among other features. The third issue is the products or services the clients expect from a firm. It is also important to consider whether there are other benefits that can be added to the product. Based on these factors, a firm can come up with the expected product and confirm that it is what the clients expect (Hussein, 2015; Sun, 2010). They can also devise supporting and facilitating product and services as well as explicit and implicit services (Hussein, 2015). According to Parlaktürk (2012), product and service variety plays an important role in addressing consumer behavior, which can improve a firm’s competitiveness.

Walmart and Amazon provide the largest product variety albeit through a different medium. While Walmart focuses on physical stores, Amazon strategy is through the internet-based system. The main similarity between the two firms is the variety of products they provide. For instance, at Amazon, products are available in different quantities, product type, item type, price, and categories (Chiles & Dau, 2005). On the other hand, Walmart categorizes within its stores into discount stores, supercenters, and neighborhood markets. The objective of Walmart management is to ensure that customers have a variety at a lower price (Chiles & Dau, 2005). The two firms mostly focus on price, selection, and convenience. However, they differ in the overall strategy based on their organizational goals. Walmart focuses on using the three aspects to push prices down sustainably. On the other hand, Amazon’s main strategy is improving selection to provide more products to consumers (Chiles & Dau, 2005).

Relationship and Experiences

The need to maintain closer relationships is one of the major objectives of firms today. Eisingerich and Bell (2014) assert that companies in the 21st century have realized the importance of building and maintaining relationships with their clients. Moreover, a positive relationship between the two influences customer trust and loyalty and influences their decisions to purchase from the firm. However, the relation requires the commitment of the firms and the consumers. In particular, companies must consider the client expectations of the products and services (Eisingerich & Bell, 2014). Customer relationship management is an effective strategy for enhancing supply chain efficiency. Kumar and Shah (2015) claim that customer relationship management has played an important role in reducing operational costs yet clients purchase more and refer others to a firm. Brink (2009) further states that maintaining relations is important in creating customer value before and after every purchase. Considering that the main objective of supply chain efficiency is creating customer value, most of the firms take measures to ensure that they maintain good customer relationships.

Peapod has successfully used customer relationship in its quest to become a leading firm. The company does feedback analysis and uses that information to meet customer expectations. Muther (2012) states that the firm has a customer loyalty of about 80%, which is extremely high compared to rival firms. Peapod’s strategy confirms that customer relationship management makes it harder for customers to switch brands. In addition, they record more sales since they get more referrals from their regular customers.

Conclusion

Indeed, the key to real customer value is effective to supply chain management through various strategies. Firms can achieve the objective by understanding their customers and responding to their needs by creating products and services that meet their expectations. Therefore, they need to get customer insights before they make new products. It is imperative to collect data about the customers to understand their tastes and preferences, cultural norms, product usage, as well as possible alternatives in the market. It is also imperative to consider the price of goods and services. The intense competition today has forced many firms to focus on strategies that can reduce their operational costs to avail products and services at lower prices. Firms have come up with flexible supply chain strategies to respond to the changes in customer preferences as soon as possible. At the same time, it is imperative to ensure that consumers have access to a variety of products and services. However, there is a need to understand the diverse customer needs to create the right varieties. Such an objective is only possible to achieve when a firm takes customer relationship management seriously. Moreover, they get real-time data about all aspects of the client. Firms that have successfully used these aspects include Samsung, Zara, Amazon, Walmart, and peapod. Their triumph affirms that creating customer value is the most important thing in supply chain management.

Also look at some of our business services

– Business Essay Writing Service

– Business Dissertation Writing Services

– Business Report Writing

– Business Assignment Help

– Business Planning Writing Service

– Business Assignment Writing Service