Define And Improve The Repair Technology And Defects In Aged Buildings In Hong Kong

CHAPTER 1: BACKGROUND OF RESEARCH

1.1 Introduction

Buildings are made to first and foremost shield its users from external forces such as the weather; rain, wind and extreme temperature. This is an important function as it allows users to enjoy maximum comfortability while performing indoor tasks. According to Wong (2017), Hong Kong’s is home to around 30,000 which are aged 50 or more years, a figure that keeps rising, and is set to multiply in the next five years (Chan, 2004). The number is all the same disappointing because nearly all the mentioned buildings need facelifts, including all features such as doors, windows, walls, life and safety, air-conditioning systems and electrical systems. The structure of a building should not only be safe to prevent hazards from happening but also allow any future risks to be mitigated in time. The Mandatory Building Inspection Scheme/Window Inspection Service (MBIS & MWIS) is 2012, the law that requires any new buildings within Hong Kong and the whole of China, in general, to undergo comprehensive statutory inspections to identify any faults which may lead to adverse effects. The inspections are carried out by a registered government inspector, and the repair works are prescribed to ensure that they meet all the statutory legal standards, such as the fire safety ordinance 572.

Old buildings will not result in problems unless there is inadequate maintenance. The problem being experienced in such buildings has caused them to be named as “Aged Buildings” because they are old. In Hong Kong, there are over 50,000 residential buildings that have been developed in the 20th century and are over 30 years of age (Tam et al. 2015). Such a figure represents about 0ne-third of the residential building stock that is in Hong Kong. It has to be understood that in this study, the more prestigious residential areas also accounted for some Aged residential buildings. However, the value of such properties has caused them to be highly maintained. When examining the ownership scheme of buildings located in the older sections of the urban areas, it is possible to note one side of the problem. The owners of such buildings are the cheap ones when owners occupy them. Majority of such buildings have been multi-tenanted with the majority of sub-letting. In other cases, it can be an old ‘lady’ who depends on such housing to maintain a living. Majority of the buildings have not been properly looked after. Even with the provision of the management, there is only the caretaker(Chan, 2019). There were no resources for maintenance and the repairs that were done was due to the urgency to breakdown basis. In most cases, the repairs that were done arose from the Housing Authority as a Repair Order. Due to lack of maintenance, the buildings became ‘Aged buildings.’

In Hong Kong, the legal liability and necessity to maintain the old buildings by the owners were very low. The owners habitually developed the attitude of waiting until there were many problems. The works of repairs and maintenance were termed as problems of the coming days. Even with the disaster that occurred in Mongkok, house owners failed to embrace safety and maintenance practices. To handle such problems, there is a need for the Hong Kong government to enact suitable legislation that will raise the awareness of owners by making them liable to maintain and manage through a statutory obligation. People who can afford to live in an improved environment would have moved out of such areas. The less affordable individuals would have been left behind and they may not be able to have some monies to carry out maintenance and repair works. There are situations whereby the owners have been sub-letting their housing units to get little income that will support their living. Even with affordable owners, they were only spending on their units internally and neglecting the external part of the house.

While maintenance of old buildings is a means through which one caters for historical preservation of a building and that of the community in general, it is an activity that can build up to disastrous consequences in the long run if not performed clearly, or according to the legal requirements. Further, built assets are defined by an aging trend, and therefore, a greater need for maintenance in the future, as buildings become older (Leung, Sing & Chan, 2015). Durability and maintainability, in this case, remain the major ways through which longer service of buildings may be attained. Nevertheless, achieving designs which are a hundred percent maintenance-free (such that they are perfectly durable) is technologically and economically unviable, partly because of the building materials that are continually being used (Leung, Sing, & Chan, 2015). It is important all the same notice the prominence maintenance-free building materials such as self-healing concrete and plastic building roofs which practically have no maintenance costs in the long term. Therefore, maintenance of built assets is regarded as a study, as professionals aim to find out any scope for minimizing costs, improving efficiency and refining performance of the facilities under maintenance. Planning, designing and managing for maintainability is, therefore, a new study topic in the market. This research is focused on identifying the common contributors and the degree of attention of defects in buildings in Hong Kong.

1.2 Aim and Objectives of the Dissertation

Aim

This dissertation aims to define the means and technologies through which repair and maintenance of aged buildings in Hong Kong are actualized and provide any suggestions any means of improving the processes.

Objectives

- To find out the scope and regulations for building maintenance as they relate to the Hong Kong government.

- Examine defects commonly observed in buildings under maintenance.

- Review the current legal requirements for older buildings in Hong Kong and the whole of China.

- Understand the different views and perceptions of stakeholders as regards the subject of inquiry.

- Recommend through a research-based building maintenance and preservation framework, any improvements to interested authorities and or attentive parties to achieve effective and effective implementation.

CHAPTER 2: LITERATURE REVIEW

2.1 Overview of Defects in Buildings

A defect, according to Cambridge Dictionaries Online, refers to a fault or problem in a thing or a person who spoils their chances of the object or the person not functioning properly as they should. If the building does not perform as well as expected, then the building is unable to provide normal service to the owners, and largely the occupants of the building and therefore necessitate that they are demolished. Building defects crop up as a result of design errors, manufacturing flaws, use of substandard construction materials, or inappropriate use and fixing of materials to the structure, and largely the maintenance of buildings over the lifespan (Leung, Sing, & Chan, 2015). The building defects can be categorized into patent or latent defects. Patent defects allude to building defects that can be found upon reasonable inspection (i.e., simple visual inspection), as they are easily noticeable, while latent defects are those that cannot be easily noticed with reasonable inspection and require enhanced inspection expertise to allow easy notice (Leung, Sing & Chan, 2015). Examples of patent defects include those discovered from moisture surveys or simple tapping tests. Latent defects include cracking of external walls, corrosion of building steel, and chloride content test of concrete. It is advisable, therefore, to take care of building defects while they are in their latent stage before they develop into patent defects.

Elimination of latent defects is presented as a difficult task, as most of the latent defects only appear when a building is already occupied and is underuse (Leung, Sing, & Chan, 2015). At this stage, it is usually very hard to access buildings and infringe people’s privacy in an aim to contain the defects. These activities are usually followed by hefty compensation as the building owner tries to relocate the occupants into a new place to inspect and contain any amendable defects that may have been discovered in the process. Added to hefty inspection and containment fees that are used in the process, building owners prefer not to go through the trouble of inspecting buildings, explaining why a majority of buildings are not discovered to be faulty till after they have attained the patency defection state.

Another reason that explains increasing cases of latent building defects is the inadequacy of the design, which prevents any further improvements in the design. This is especially true for Hong Kong buildings built before the 20th century, right before building regulations such as the Public Health and Buildings Ordinance act existed. The mentioned regulation necessitated all residential buildings within Hong Kong allow open spaces inside the building for air conditioning purposes (Govhillmystery, 2016). Such buildings normally had no air conditioning facilities, and renovations to add air conditioning facilities usually prove hard to implement as the limiting design capabilities of the building prove to be a hindrance. Other renovation features which are hard include thermal insulation and reduced energy consumption facilities. Latent defects equally need time to appear, and can therefore not be noticed early during the lifespan of the building. Most of the latent defects are usually related to building finishes and materials. They remain non-structural defects and therefore, do not bring about physical injuries to building occupants. Nevertheless, latent defects such as the development of mold can result in health complications which may be expensive to treat or take care of.

A safe and healthy building that is free of, or one that has contained latent and patent defects can afford occupants healthy living and working environments through which they can carry out their humanitarian activities in a creative and comfortable manner. Dilapidated buildings, on the other hand, can render building occupants to increased physical and health dangers, in addition to investment losses to both the general public, the state, and building owners (Chan, Hung, Chan, & Lo, 2014; Subcommittee on Land Notice, 2010). On this note, it is, therefore, important that buildings receive proper inspection and maintenance to allow that members benefit from the safe and healthy conditions and that both property and lives of the building’s occupants are secured. Laws such as the Mandatory Building Inspection Scheme (MBIS) in Hong Kong (Chan, Hung, Chan, & Lo, 2014), should come into play and facilitate the process of proper building inspection.

2.2 Defects and Various Terminologies Used in Construction

The term defects can be interchanged with other construction terms such as repairs, fault, quality deviations or failures, rework, snags and non-conformance. Snags have emerged to be a widely used term in the construction industry. Snags are known to be items of quality failure that are evidenced around the completion phase of construction by an expert known as ‘snag identifier.’ While detect reporting or snagging is the procedure of identifying and fixing the snags. Snagging is a procedure that checks for defects in a building and rectifies them before it is allocated to the new owner(Chan, 2019). In this context, snagging issues are works that need some attention after the completion of the main body.

Rework is another term that is known as the procedure of making an item to follow the original requirements through correction (Chan, 2019). It can mean undertaking something or building activity that was performed incorrectly during the first time. The definition suggests that work is redone because of a defect. As researchers have made efforts in understanding and describing the scenario of defects and rework, the existing literature has focused on the key project environment and the entire construction industry.

2.3 Overview of Aged Buildings in Hong Kong and Overseas

Building dilapidation remains a great problem in Hong Kong, one which needs to be resolved immediately if occupants and property managers are to enjoy an increased performance from the buildings (Subcommittee on Land Notice, 2010). This is especially true as the defects continue to be replicated in almost every aged building in the city, with the building information being depended upon, remaining unreliable for most parts of the inspection process. Very few property managers have databases or files that document the progress of the building throughout its lifetime, including items such as maintenance and renovation records.

Many aged buildings in Hong Kong have been converted into restoration centers or have been labeled as historical centers by the local authorities. According to the Antiquities and Monuments Office (2019), there were over 917 graded historic buildings in Hong Kong in 2016 (442 categorized as Grade III, 332 as Grade II, and 153 as Grade I), and the figure keeps increasing. Two hundred three of the historic buildings are the property of the Chinese Government. Seven hundred fourteen are owned by private citizens and businesses within China. Most of the mentioned historic buildings have served the Chinese for over a century, and their conversion into historic centers means that their lifespan is not yet complete. The number does not include the number of private residences, business centers and tenement buildings in Hong Kong. A 2010 report from to the Subcommittee on Land Notice appointed by the Hong Kong government to investigate the number of aged buildings in Hong Kong mentions that at the time, there were over 4,000 buildings in Hong Kong which were aged 50 years or more. The building materials used for construction purposes half a century ago remain of lesser quality than those used in the 21st century (Tam et al. 2015). The 2010 Subcommittee on Land Notice report, further documents that the design working life of a conventional building within Hong Kong as well as other cities within China is averagely 50 years, and that the older a building is physically, then the more likely it is to succumb to building condition issues that require attention over time.

A study in New Zealand in 2011 on building performance measures suggested that 75% of homeowners had to enquire for defect rectification from the house builders (Chan, 2004). The high number of callbacks has been used as an indicator and quality performance in aged buildings. The residential sector in the UK has also regularly experienced the low-quality performance with the high number of defects in the aged residential buildings. A study in 2004 in the UK on 600 aged residential buildings recorded about 367 defects (Ho and Yau, 2004). Also, in the UK, research was conducted in four years from 2007, whereby 2243 buildings were examined by a prominent home snagging firm. The results suggested that about 130,000 defective items were identified. From the initial examination of 55,000 defective items, it was noted that 65% of the defects resulted due to poor workmanship while 16% was due to omission. Research in Australia has proven that the defects in aged buildings are similar to what is experienced in other countries(Chan, 2019). About 42,000 homes in Australia were investigated for various types of defects in 2004. It was evident that majority of the defects were cracking, illegal building, roofing, framing and rising damp. Roofing and framing issues were major defects that increase the complication of other problems.

2.4 Types of Defects Found in Hong Kong Buildings

Defects have emerged as key features in many construction projects with vast harmful effects on the project stakeholders. Defects cause a reduction in levels of satisfaction, develop conflicts among stakeholders of the project. The homeowners of constructed buildings expect that the new houses are free from problems until there is the occurrence of wear and tear (Lee et al. 2008). Nevertheless, this has not been the case as the majority of the new buildings have been found to have many defects. The new residential buildings have a high chance of having quality defects, which makes the homeowners frustrated. The vulnerability of the aged buildings implies that the house owners have to suffer the burden of defects sometimes with no recourse to the warranties of the house building developers.

Most of the aged buildings within Hong Kong suffering from the problem of latent or potent defects have been exacerbated by the building boom which took place from the 1960s through to the early 1970s. At the time of the building boom, many large buildings were completed within a short period, therefore, raising the chances that substandard building materials were used, in addition to lack of sufficient time for the used building materials to settle. Chan, Hung, Chan, & Lo (2014), point out that, at this time, the construction speed of the buildings was prioritized and was therefore attained at the expense of quality. The conditions of these buildings have, therefore, deteriorated with time, and are even in worse conditions than those that were built during the plague period (Govhillmystery, 2016).

Various building defects exist in aged buildings. Of these, the most common remains structural defects which have resulted in cracks or collapse of the whole or part of the building; defective electrical wiring and lighting, defective or faulty plumbing and inadequate or defective drainage systems. The defects may also be as a result of damage by land movement or earth settlement (Lau & Ho, 2010). Defects, particularly those in urban building settings, bring about urban decay, which is one of the contemporary issues in cities of developed countries worldwide. Other common defects that can be found in residential buildings are as mentioned below:

- Blemishes:

There are three types of Blemishes. These include Scaling-the loss in the surface mortar or mortar surrounding the coarse aggregate particles on a concrete surface; Honeycomb and Void-both of which are defined as the mortar that fails to fill voids around the coarse-aggregate concrete particles. Scaling usually occurs in cyclic freezing and thawing environments, with the major causes being one or a combination of the following factors: (1) deprived concrete quality; (2) poor construction method; (3) exposure of the building to corrosive salts; (4) and exposure of the poorly constructed building or concrete to deicing salts (Lee et al. 2008). Honeycomb and Void, on the other hand, occur as a result of stiff or impractical concrete, separation, jammed reinforcement steel bar, inadequate consolidation, and unsuitable insertion practices.

- Corrosion of Reinforcement Steel

Corrosion, as defined by the ASTM (American Society for Testing and Materials) terminology G15, is the chemical or electrochemical reaction between a material, especially a metal, and its immediate environment resulting to a deterioration of the material as well as its properties. In the case of reinforcement steel for instance, when corrosion takes place, the volume of corrosion products will be thrice to six times greater than that of reinforcement steel, increasingly resulting to great disruptive tensile stress on the surrounding concrete, bringing about more cracking, access of tough weather conditions and increased corrosion. In more severe cases, spalling of concrete may take place finally falling.

- Dampness

Dampness in buildings can be separated into three areas or causes, including rising dampness, penetrating dampness and condensation. Dampness is known as excessive moisture levels in the house. The aged buildings have been experiencing damaging failures due to dampness and need to be taken care of. The effect is that the brickwork has been highly saturated and damaged, destruction of mortar joints, timber structures rotting and defects by steel and iron corrosion (Lee et al. 2008). Prevailing rain and wet wind will cause water penetration through the walls of old buildings which destroys them.

- Water Seepage

Water seepage remains a common defect of buildings, not only in Hong Kong but also in other parts of the world (Subcommittee on Land Notice, 2010). Water seepage causes damages to contents of the building, including reinforcement corrosion, delamination and faster aging, therefore bringing about reduced functionality of the building.

- Peeling Paint

Though peeling of paints brings about no structural defects to buildings, the aesthetic value of the building is lost. The building thus looks older and lifeless, therefore caring away occupants or attracting the attention of building authorities. Multiple reasons explain why a paint job could be messed up, but a few contributors can be linked to the same: lack of adequate surface preparation beforehand, painting on moist or damp walls and use of sub-standard paint.

- Roof Defects

Roof defects generally allow seepage of water into the building, affecting mostly the top tenants in a story building. The seeped moisture contributes to the growth of bacteria and mold that may affect occupants’ health. Various causes may be linked to roof defects; these include: (1) deterioration of waterproofing layer on the roof; (2) leakage at access doors or top hatch doors; (3) malfunctioning enclosure for water reservoirs such as top placed tanks; (4) fissures of parapet walls in turn affecting the waterproofing membrane of the roof; (5) and extreme engagements of construction joints (Ho and Yau, 2004).

- Spalling

Spalling is usually caused by water entering a surface and forcing it to peel, pop out or flake off. Bricks, concrete and natural stone remain the single most affected surfaces. Usually the spalling is as a result of moisture content available in the concrete.

- Cracking:

Cracking can be categorized into structural cracks and non-structural cracks. Structural cracks will eventually affect the structural integrity of a building, according to Lau, (2006). Excessive movement of the building structure, unwanted ground settlement, increased overloading or weakness brought about by corrosion or deterioration of materials remain some of the main reasons for cracking of buildings.

- Popping or falling of tiles

According to Cheng (n.d), this defect is very common, especially when tiles are placed on ceilings and walls. Various reasons explain these defects: (1) installation of the tiles without proper cleaning; (2) lack of proper grouting upon installation; (3) and that the installation adhesive has not been applied correctly.

- Defective Plaster Rendering

Plaster is similar to mortar coating the inner side of the walls in a house while rendering coats the outside walls. Plaster ensure that the walls inside are smooth, easy to clean and have a better appearance. Also, it acts as a protection against fire and abrasion-resistant. The renders are made to protect the walls from weather interference. The defective plaster rendering will exist on ceiling, column and external walls. The cause is normally biological attacks that emerge from thermal stress, air pollution, condensation, evaporation, penetrating rain and dehydration. There is decomposition, breakage of parts and the shrinkage in the substrate will cause rendering to crack. The various types of defective plaster rendering that can be experienced in aged buildings include holes in plaster walls, cracking in plastering, shrinkage cracking and falling of plaster from the ceiling.

- Unstable Foundation

Foundation is paramount in supporting the building and all its loads. The foundation needs to be constructed from a material with high strength to ensure stability is enhanced on the ground. When the foundation experiences difficulty, it will cause the building structure to defect. It is noted that the aged buildings experience foundation problems which cause cracking of walls and floors, building collapsing and wall leading. Movement of the soil due to water flow is regarded as a major cause of unstable foundation. Buildings that were constructed in hill slope areas have a higher probability of experiencing landslide, which can cause the collapse of the building (Ho and Yau, 2004). The material used in building construction has a high possibility of affecting the stability of foundations. The materials used can impact the concrete strength and this requires the foundation to be constructed from materials of high strength and do well in groundwater.

- Insect Attack

Insects usually attack timber that that has high moisture content. Termite attacks cause a great danger to digestible timber that is used in trusses, beams, rafter and wall plates. Pressure spraying using insecticide or fumigant has to be carried out to treat affected timber. Termites usually attack various types of timber such as meranti, ironwood, selangan batu and plywood. Because the aged buildings touch the soil, they have a high susceptibility of being attacked by insects such as termites. It is a requirement that the beams of buildings have to be supported through old stumps.

2.5 The Structure of Building Control System in Hong Kong

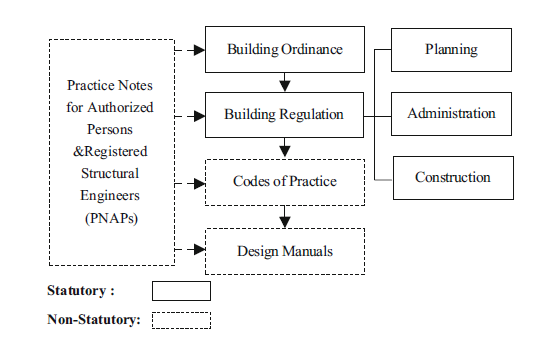

In Hong Kong, the Building Ordinance is known to be the highest statute law that regulates construction procedures and works. The Building ordinance is enacted by the legislative council. The Building Control System framework was established under two sections. There is the statutory section made of the Building Ordinance and the subsidiary legislation that coordinates the execution of the Buildings Ordinance Regulations such as the building administration regulation, private streets and access roads buildings regulations, demolition works buildings regulations, building planning regulation and building construction regulation.

The Building Ordinance entails the review and authorization of project drawings, supervision of implementation stage of construction, appeal system and maintenance after construction approval (Leung et al. 2015). This section also maintains technical construction standards and maintains old buildings. The regulations will also entail the planning, construction and demolition, administrative management, pathways, private roads and health equipment engineering, among others.

The functions of the Building Control on Building Management is illustrated in the figure below.

Figure 1: Outline of the building control system.

It has to be understood that the non-statutory section entails design manuals, codes of practice and registered structural engineers and authorized persons.

2.6 The Building Control System as the Supervision Institution

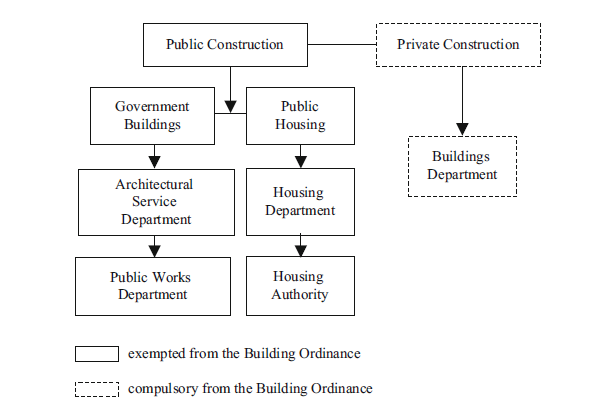

In Hong Kong, the building industry is categorized into private construction managed by developers and the public construction regulated by the government. The public construction is run by the Housing Department and Architectural Service Department on behalf of the government (Leung et al. 2015). For private construction, it is under the Building Department based on the law of Building Ordinance and supplementary regulations. According to the new private buildings, the Building Department examines and accepts building plans, perform audit checks on-site safety and construction work and offer occupation permits after completion of new buildings.

Figure 2: Outline of the supervision institution

From the above figure, it is evidenced that the Housing Authority of Hong Kong is excluded from the Building Ordinance for the public housing estates construction.

2.7 Scope and Regulation Related to Hong Kong Government Control

- Registers

In Hong Kong, the government utilizes the permit to manage and coordinate all works of constr

- Authorized architects

- Authorized engineers

- Authorized surveyors

- Registered structural engineers

- Enumerated Geotechnical engineers

- Enumerated general contractors of buildings

- Enumerated specialists contractors for demolition works

- The enumerated foundation works specialist contractors

- Enumerated site formation works specialist contractors

- Enumerated ventilation works specialist contractors

- Enumerated specialist contractors for ground investigation works

- Approval and Consent

The Hong Kong government has stipulated that an owner has to employ Authorized Persons (AP) to act as a representative when they wish to carry out building works. The BA4 form has to be completed to notify the Buildings Department. After AP files for approval, the assessment and drawings have to be submitted to the Building Department. The BD issues the approval letter and approval chop of the drawing if they manage to meet the legal requirements. If it does not fulfill the requirements, there is a need to re-submit.

After work has commenced, the AP has to apply for the consent whereby a standard BA8 form has to be submitted to inform the Building Department and obtain the agreement. The BD will review the environment another time and issue the consent. After the BD103 consent is issued to the AP, construction work is not authorized to start (Leung et al. 2015). The reason is that the authorized person must notify the Building Department that work will begin in 7 days advance and a standard BA10 form to be submitted. After starting the work, the Building Department will conduct close supervision to certify that the works meet the design assumptions. Under geotechnical works, supervision is enhanced by the geotechnical engineering office. After completion of work, the AP will submit the BA14 form, inspection form PNAP242 for foundation, documents which are listed in the approval letter such as cantilever report or concrete record and as-built drawings to notify the Building Department.

After the completion of a new building, the authorized person has to issue a standard form BA13 to notify the Building Department. BD will review the documents and the completed work; when there is no problem, the owner will be issued with an Operation Permit (OP) (Lau, 2006). The authorized person also has to issue other forms when they are required. For instance, BA11 to authorize another contractor appointment, BA7 for urgent works or the BA21 for replacement of another authorized person who is not located in Hong Kong.

- Supervision and Audit

In all the private building sites, the Site Monitoring Section is responsible for undertaking systematic inspections where building works are taking place. The aim is to denote irregularities of works that can cause potential hazards to the public or non-compliance with the regulations and Buildings Ordinance. The inspection concentrates on quality aspects of the building works and site safety to ensure compliance of the relevant provisions of the Building Ordinance (Leung et al. 2015). When irregularities in terms of quality or site safety are detected, remedies from registered contractors, structural engineers, or authorized persons will be carried out. Disciplinary actions and prosecutions under the Buildings Ordinance will be instigated against those concerned.

The SMS also undertake instant reviews on active sites of constructions on elements of superstructure works, foundation integrity and structural safety. Such a procedure for building works auditing assist in presenting structural safety-related malpractices that are favorable to substandard building works before incurring higher costs. After obtaining reports on safety irregularities emerging from demolition and building sites, the SMS conducts follow up actions.

- Landslip Preventive Measures Programme (LPM)

In Hong Kong, the office of Geotechnical Engineering has the mandate to perform an initial investigation of private and government retaining walls and human-made slopes, which pose a risk to property and life. The GEO conducts key slope upgrading works for other Government departments. Since 2006, the Buildings De4partment has spent over $ 9.5 billion in upgrading works in pre-GEO substandard slopes under programs such as LPM (Subcommittee on Land Notice, 2010). The LPM initiative controls the investigations, in a priority of risk-based of the human-made slopes that existed when GEO was being set up. The government was highly committed to improving slope safety and the upgrading and maintaining the long-term plan of slope features in the New Catalogue of Slopes which facilitated the introduction of a ten years LPM project. The extended LPM project of 2000-2010 featured substandard human-made slopes of high-priority in the catalog of slopes.

In the execution of the recommendations of the Slope Safety Review carried out by the later Works Bureau, the GEO managed to gather more resources to boost the LPM programme. The aim was to finish the investigations and the upgrading works on the human-made government high-priority slopes recorded in the catalog of slopes of 1977/78 for the five-year period that started in April 1995. Investigation is also carried out on identified slopes in the New Catalogue of Slopes that pose dangers and are upgraded through the LPM programme.

The government policy ensures that the human-made slopes transform to a natural look to minimize the visual impact and facilitate environmental improvement. Therefore, the GEO ensures high slope safety standards and is committed to improving the human-made slopes appearance by taking this as key result areas of management systems of slope safety. To attain this, the slopes that are upgraded under the LPM are issued with landscape treatments. In other cases, vegetation acts as a cover for slope surface. The use of a hard surface cover acts as the last alternative on slope safety grounds and repairs for landslide scars.

2.8 Maintenance of Aged Buildings Due to Construction and Design Defects

Buildings cannot stay as new in their entire lifetime. After the completion of buildings, they will start to deteriorate and this calls for the process of maintenance. As Chan & Hon, 2016 suggest, maintenance is the merging of all administrative and technical actions such as inspection which aims at retaining the building or restoring it to a condition that can carry out a required function. Maintenance entails the expenses of usual custodial repair and care, annual contracts of maintenance and payment of staff undertaking the maintenance procedure.

The act of building maintenance is a key aspect which is reviewed during the early stages of design construction to improve the quality of the building. For the aged buildings in Hong Kong, building maintenance needs to follow several objectives like replacements, repairs, renewals, protection, modification, decoration to safeguard the building’s internal surfaces and to clean (Lau, 2006). There are other building maintenance objectives. It will aim to ensure that the associated building services are in proper condition to make the building sufficient for use. It ensures the state of the building adheres to the statutory requirements. Finally, it also aims to facilitate maintenance practices that will improve the value of the physical assets of the aged building.

2.9 Building Maintenance Management

Building maintenance is regarded as work that is carried out to preserve, restore, or upgrade every building parts to an accepted standard and to maintain the value and utility of the building. As studies suggest, the activities of building maintenance have attained a 50% level on the annual construction processes. In Hong Kong, it is noted that in the past five years there has been an increase in the gross value of general trades that entail repair, decoration, maintenance and works of construction at minor locations of works. Studies in Hong Kong have illustrated that maintenance has been an avoidable task both in the private and public sector as it is viewed to add little quality to the building and to consume sparse resources that can be utilized better (Chan & Hon, 2016).

Management of the buildings will entail evaluating performance and maintenance management has to be carried out on the building (Sing et al. 2019). For the maintenance manager to set priorities and evaluate performance, there is a need to consider the performance and function of buildings. The appropriate standards of the buildings will rely on the viewpoint of the users and their primary needs. In Hong Kong, the Building Maintenance Department has a variety of function to undertake, such as:

- Planning and repairing building facilities to the recommended standards

- Carrying out preventive maintenance

- Creating and executing a frequently work schedule for maintaining facility and equipment operation and curb major problems

- Make contract specifications and inspect work done by contractors to guarantee compliance with the requirements

- Review plans for new buildings and equipment installations among others

The building maintenance unit has the role of preserving all the infrastructure and facilities in a building. The support systems in the building such as air intake, safety security, pest control, landscape, sanitary and plumbing system, firefighting system, air condition system and lift system are in good working condition(Chan & Hon, 2016). Consequently, the purpose of building maintenance is to improve the economic and aesthetic value of the aged buildings in a way that it will main the safety and health of the occupants.

2.10 Developing a Policy of Maintenance for the Aged Buildings

A maintenance policy is a plan having ground rules for the distribution of resources between the available maintenance actions for the management (Davies, 1998). The goal of the maintenance policy is to preserve the appropriate state of the buildings through the most economic measures. It is required that the building maintenance have a clear set of methods and objectives to be implemented to keep the buildings safe and fit for use. It has to present an outline from where management operations and maintenance of the building are set. The building management policy will stipulate the guidelines based on recommended technical standards, budget control, servicing operations, legal considerations and relations with housing tenants (Lau, 2006). The target should be reducing the cost of maintenance or reaching a preventive type of maintenance. Additionally, it is necessary to avoid faults that emerge during construction, design and preventive maintenance.

2.11 The Different Views of Stakeholders on Building Repair and Maintenance

- Designers’ Perspective

Naïve designers are likely to ignore the role of the users and client and decide to make their own decisions. However, designers have to ensure that they have taken into consideration the needs of clients and accommodated all the requirements. Indeed, this issue arises due to misunderstandings on both parties. Designers have a vast knowledge of building design, but fail to get any feedback after a building is completed (Sing et al. 2019). There is a high inclination to modify the nature of a building from the classical craft procedure to an assembly of manufactured components. At first, the designer is expected to give specification on a wide range of products, all of which have the potential to meet performance requirements. Also, designers face a great deal of pushing to use a given product more than the other, which bombards them with a surplus of public material. This makes the designer use any equipment that lacks approval in practice, which poses a risk of failing to meet the requirements. Also, it can cause the designer to use any equipment or tool that they are conversant with irrespective if it’s the right choice.

- Owners Perspective and Maintenance

Owners have a great challenge to attain greater demands to increase the maintenance standards having less capital, less time and staff than ever before if no work is to be carried out. End-users and clients tend to blame the construction industry for offering products that fail to meet the expectations. The reason is that the end-users and clients are not well catered for in the process of design, making their objectives not reflected. The owners of buildings highly focus on project cost at the expense of fore-coming running costs (Chan & Hon, 2016). The owners and house users are the initiators of maintenance and other parties like the public can influence the work undertaken. The primary aim of building owners is to keep the asset value to ensure a long-term investment that is free from trouble and capable of guaranteeing a satisfactory and continuous return.

2.12 Hong Kong Repair Technology

- Concrete Work and Repair

- Primers

This will have to be set according to the standards set by the manufacturer of the certified proprietary motor repair. The rust inhibitors will have to contain pigments of titanium dioxide in a reformed aliphatic as a binder (HKIS, 2009). The reinforcement primer of cement has to be approved by modified cement polymer in line with corrosion resistance primers. Epoxy primers reinforcement can be approved by components of resin epoxy delivered in pre-weighted quantities. The primer needs to be used before the end of pot life or shelf life.

- Reinforcements

Reinforcements for replacements and dowel bars are required to meet all requirements in the specifications.

- Bond Coats

This will observe the manufacturer’s specifications of the repaired motar. Acrylic bond coats will be approved as single materials of components according to copolymer emulsion or acrylic polymer(HKIS, 2009). Cement bond coats will be accepted as materials of cementations blend with polymer emulsion.

- Cement

This will be ordinary Portland cement of BS EN 197-1:2000 unless there are other specifications(HKIS, 2009). The storage, delivery and quality of cement need to meet all aspects of the specifications.

- Drainage Repair

When fixing gutters, they will be set to falls of a minimum of 1 in 300. The gutters and cast iron pipes will be joined by a compound of cold caulking and gaskin. There will be a minimum of 1m centers when fixing cast iron gutters with screwed brackets. For the plastic pipes and gutters, they will be connected based on the recommendations of the manufactures. There will be no fixing of roof outlet gratings until there is completion of all work on the roof. It is recommended that fittings and precast concrete pipes should observe the BS 5911-1:20002(HKIS, 2009). Concrete pipes should have a wall strength and thickness that is equal or more than what is specified. Inspection units or bolted access doors will be made at all bends, base of soil stacks and branches other than anti-siphon pipes.

- Finishes Repair

During the preparation for screeds, dust, oil, dirt and other materials will have to be removed and cleaned on the concrete surfaces. There will be brushing off a neat cement slurry on the existing surface before smearing the finish. Also, an approved bonding agent of proprietary type can be used in place of cement slurry. When laying monolithically the floor screeds with the base, it has to be applied as one coat under three hours after setting the base. The laying of screeds within bays and timber battens should not surpass 15 square meters. Screeds that are air entrained need to have a dry density less than 1200kg/m3(HKIS, 2009). The surfaces of screeds will be finished by either a stiff brush of slightly roughened texture, a wood float of even surface texture or a steel towel of smooth un-textured surface.

- Roof Water Proofing

The entire roof has to be left watertight when there is no work in progress. The contractor is expected to offer coverings in places they are not replaced or are missing through sheeting or tarpaulins to cover the roof. Tapes and sheets will be used to seal the overlaps that are properly set into outlets(HKIS, 2009). During construction, all outlets of the roofing will be covered to prevent the fall of debris into pipes. There shall be priming, laying and finishing of the flexible sheet proprietary membrane according to the specifications of the manufacturer.

- Steel Works Corrosion

There shall be the protection of all finishes of steelworks against scratching, damp, corrosion and damage. Stainless steel will be smeared with stripped coating or masking tape. For anodized aluminum and other corrosion will be removed before construction. Surplus adhesive will be used to get rid of non-damaging solvent and then washed down (HKIS, 2009). Steel will be applied with painted finish and a process of hot-dip galvanizing will adhere to the BS EN ISO 1461 specifications.

2.13 Singapore Repair Technology

- Concrete Repair

During design mixes, there is a need for submission of a report by the contractor to cover all mixes of concrete to the SO Rep to enhance approval (Housing and Development Board, 2012). The concrete workability will be in a way it can be compacted, worked around reinforcements and shuttering corners, provide the recommended surface finish and indicated strength. The mix design will ensure there is workability. During the days of concrete, there will be assessment of workability on the site at the mixer discharge point by using slump test that obeys SS78. The concrete will be rejected when there is deviation of the measured slump by over +or – 25mm of the agreed value.

- Drainage Repair

The Water Supply Department has the authority to approve all pipe fittings and pipes unless stated otherwise. The SO Rep has the mandate to undertake tests on materials when required and those on the site. The pipes and fittings will be internally lined cement mortar that obeys the clauses in BS EN 545. There is no bending of all stainless steel pipes and the internal and external surfaces have to be clean and smooth. The fittings of steel pipes will be of copper alloy compression fittings or fitting joints of stainless steel press. An iron distribution main that is set with a diameter of 100mm of the underground ductile and a sub-main of 80mm ductile iron that meet the specifications of BS EN 545(Housing and Development Board, 2012).

iii. Finishes Repair

All the concrete screeds have to be finished with at least a two-pass power towel. Finishing should not include cement dust sprinkling, water on the screed or cement grout. The concrete screed will be immediately moist cured for seven days or with certified curing elements (Housing and Development Board, 2012). A water test will be performed to ascertain the water tightness of the floor area around the water outlet and pipes in the balcony and kitchen. A polythene sheet will be used to temporarily block off the floor water outlet before the water test.

- Roof Water Proofing

All roof surfaces to be applied sand or cement screeds have to be made clean and made clean before applying screed. The screed will have to be damp and properly cured to curb cracking and shrinkage. The contractor has the mandate to seal all openings in the roof slabs with a higher grade mortar or non-shrinking mortar cement to be similar to that of the surrounding concrete(Housing and Development Board, 2012). There has to be provision of base liquid polyurethane that is waterproofing membrane in the service pipes at 300 mm radius from the outlet center.

- Steel Works Corrosion

The contractor is expected to subject structural steel members to galvanizing treatment service which is in the HDB material list of Approved Galvanisers. Steel having a 6 mm diameter or more, the minimum mass of coating will be 610 kg per square meter and the minimum local coating mass as 500g per meter square (Housing and Development Board, 2012). The coating process will be smooth, continuous and free from stains flux. After galvanizing, chromating will be done as a post-treatment. All galvanized steel is then stored in a well-ventilated dry place to prevent rusting.

CHAPTER 3: METHODOLOGY OF STUDY

This section seeks to examine the extent and common defects as well as levels of satisfaction of new homeowners to improve quality standards in residential buildings in Hong Kong. The chapter presents a research design, paradigms and viewpoints that facilitated the research. An overview of the main sources of data is provided together with ethical issues, reliability information.

3.1 Research Methodology

This will indicate the rationale and nature of the selected methodology. The methodology is a technique in a research study that involves a body of methods. As Sing et al. 2019 suggested, a research methodology means the data that is collected, the place it is collected, when it is collected and the technique of analyzing the collected data. The choice of research methodology is dependent on the available resources, norms of practice, research objectives, epistemological issues and other factors.

- Qualitative Research

This method aims at examining questions that develop an understanding of the experience and meaning of the social worlds and human lives. It is a research approach that investigates behaviors, experiences and attitudes through observations, interviews and focus groups. It gathers non-numeric data, which is analyzed through interpretive means. In this study, qualitative research will be used to collect detailed information to enable a full understanding of the defects and technology maintenance in aged buildings.

- Quantitative Research

This approach aims at counting and classifying aspects and developing statistical figures and models to explain what is observed. This method develops statistics by using survey research like structured interviews and questionnaires. Through this method, quantitative terms like patterns, numbers, frequencies and relationships will be used for data analysis. This study utilized a quantitative approach to support qualitative analysis.

3.2 Research Design

This refers to the logical sequence that connects the data to the research objectives and its results and conclusion. The decisions on research design are vital for the research contribution and its philosophical background. The research design will entail the entire approach that is considered and detailed info based on where, whom, when the research is carried out. In this research study, a survey was considered as the best method for determining the common defect, the satisfaction levels of homeowners, the house building developers quality practice and existing warranties for homeowners.

3.3 Method of Research

For this study, two pilot studies were conducted. First, telephone calls were dialed to five major building companies to find out about the calls backs or records of defects from customers or house owners. It is noted that it was impossible to obtain the information as these developers claimed that they did not keep records of the calls. The suggestion was that since the identified defects by homeowners are mainly minor, they get rectified within a short time without the need of keeping a record. Obvious, there was insufficient performance monitoring of the building components, which causes poor keeping of records.

The second procedure entailed administering semi-structured questionnaires to homeowners within Hong Kong. The purpose was to test the accuracy of the questionnaire. Forty-two questionnaires were delivered and 35 were returned, which indicated a 70% response rate. As studies suggest, the suitability and usefulness of a questionnaire are determined through a pilot test that involves at least 25 participants. Therefore, obtaining 35 responses met the requirements. There was the modification of the initial questionnaire to be matched with the responses obtained from the pilot survey. Other changes dealt with the questionnaire structure. Questionnaires having Likert scales were re-written to include questions of negative and positive words to ensure there was uniformity in answering the questions.

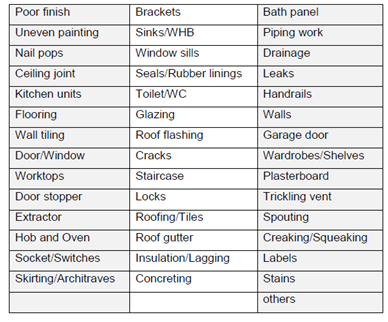

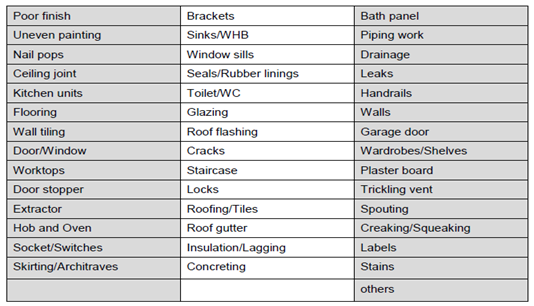

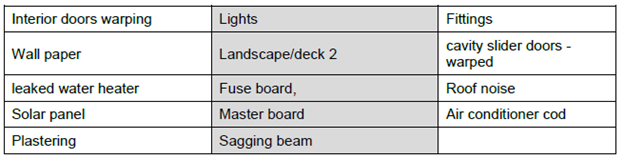

As a section of the modification on the questionnaire, there was the inclusion of the list of defects that were obtained from the previous literature. This was to ensure the realization of the objective of understanding the common defects in buildings and knowing the different perception of stakeholders. This procedure managed to obtain the record of defects from house owners. The list of defects was simplified into 43 defects for the success of the study.

Table 1: Standard list of defects offered to participants.

3.4 Ethical Issues

It is vital to make ethical considerations in a research project. In this study, ethical clearance was obtained from the University Ethics Committee. An application was submitted to the committee and approval granted. There was an attachment of other ethics application documents such as participant sheet of information, consent form of participants and questionnaires to housing users or owners. All the stipulated principles and guidelines of the University Ethics were obliged in the creation and issuing of interviews and questionnaires. Participants were informed that the research was voluntary and there was no cost involved in participating. The rights to privacy, confidentiality and anonymity to all the participants were assured by issuing a numerical code to all who took part in the research study.

3.5 Reliability

This means having no difference in research results after successful repeats (Sing et al. 2019). It was necessary to complete the questionnaires by residential homeowners. Also, in the process of interviewing, house building developers with vast knowledge and experience in new house development has to be selected. It was expected that the use of both the first survey, which is a questionnaire and the second through interviews would reduce the risk to research reliability.

3.6 Sampling Frame

- Sample size

This study focused on homeowners and building developers in Hong Kong as the main sample frame. This is because house developers are key when examining the issues or defects in aged buildings. The homeowners are vital when reviewing customer satisfaction levels. There was a random selection of the sample of homeowners in Hong Kong from data gathered from ‘What’s on,’ a firm that offers construction intelligence for building industry. The Yellow Pages acted as the source for selecting house building developers with regards to their working experience and number of franchisees.

- Sampling Method

To meet the objectives of the study, consideration was made on house developers and homeowners to dictate the sampling technique to be used. Random sampling was used to provide the correct representation of homeowners in Hong Kong. There was a generation of random numbers for the participants obtained from ‘What’s on’ using Microsoft Excel. It was necessary to create consent lists provided by Building Consent Authorities to determine the population size of the study of the homeowners (Yau et al. 2008). The total population size of homeowners for the survey was 5,700. The minimum return sample size for the population had to be determined. With the following conditions; margin of error =0.05, the population of 6,000, t-value of 1.96 and alpha value of 0.5, the sample size was found to be 362.

The second survey utilized purposive or non-probability sampling to select informative participants to represent the bigger situation under examination. It was necessary to use non-probability sampling in this research as house developers have experienced and vast knowledge when examining the matter of defects in aged buildings.

3.7 Data Collection Strategy

Collection of data for the study was based on both qualitative and quantitative research as the aim was to obtain information from participants to develop a detailed description of the phenomenon. The methods of data collection included interviews, surveys and mail questionnaire. The use of postal questionnaire was preferred as the best means to reach the research participants. The other field investigation utilized unstructured interviews. Due to accuracy in data collection in the built environment sector, it was the best reason for using interviews as a qualitative method.

- Questionnaire Survey

Primary data was gathered by submitting questionnaires to homeowners. It was expected that the use of questionnaires would give information that would increase the satisfaction level of homeowners and create awareness on utilizing defect reporting companies to upgrade the quality of aged residential buildings in Hong Kong. Research participants were recognized through the code number that was attached to every questionnaire to ensure privacy and confidentiality. One thousand thirty-two postal questionnaires were delivered to homeowners within Hong Kong. The partakers had four weeks to fill the questionnaires and return them.

- Interviews

- House Developers

There were ten house developers having franchisees in Hong Kong that were used to conduct the interview. A face-to-face interview was utilized with semi-structured questions. This ensured a deep understanding of the research objectives and its necessity to the stakeholders. It was a process that supported cross-questioning, which gave room for the researcher to seek clarification of answers (Yau et al. 2008). The topics of the interview were pre-specified, but the questions were open-ended. The selection of the house developers was based on the probability of their interview contributing to research objectives. The sample size comprised ten house developers who were adequate for the qualitative analysis.

CHAPTER 4: DISCUSSION & ANALYSIS OF DATA COLLECTED

4.1. Characteristics of the Sample

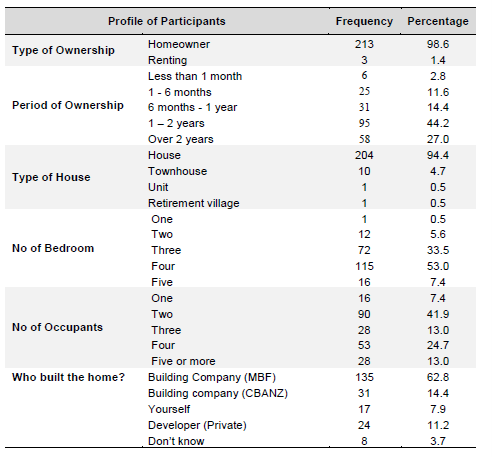

The data was obtained from residential homeowners within Hong Kong. From the 1032 administered questionnaires, there was a response of 228 with 95% being usable. There was a response rate of 21%, which was 216 usable questionnaires after performing data clean-up. Despite obtaining a lower response rate, the total number of responses adhered to the Central Limit Theorem of sample size being greater than thirty. This showed that the total responses were statistically significant. Two hundred fifty-two questionnaires were returned even though the points of delivery could not be traced through the postal agency.

SECTION A

4.2 Participants’ Demographic Information

This section comprised of several questions that covered ownership period, ownership type, type of house, number of occupants, number of bedrooms and house developer information. The aim was to understand the background of the participants to facilitate an easy understanding of their responses.

Table 2: Demographic information of the participants.

Based on the first question, Table 2 indicates that 98.6% of the research participants owned their houses while for a rental was only 1.4%. The results also indicated that 44% of the participants had owned a house for almost two years, while 27% have owned for over two years. On the other hand, 14.4% of the participants have less than one year in homeownership. The third question covered the type of house of the participants. The category of the single lease had 94% of the participants, shared lease 5% and 0.5% owned unit and villages.

SECTION B

4.3. Defects

This section involved defects that need to be observed by homeowners when they reside in a house. The participants were to denote any warranty for minor or structural component defects on their houses. The section obtained information about major defects in residential buildings. The section reveals the response rate of house developers when it comes to defect rectification.

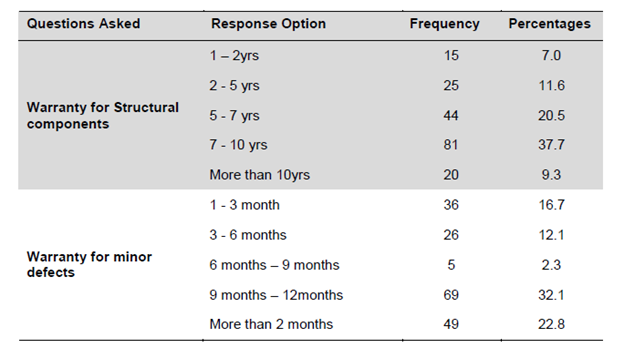

4.3.1 Warranties Offered for Homeowners on Structural Defects

In this section, the objective was to determine if homeowners understand about the warranty set out in the Building Act 2004. From the results, 37% of the participants claimed that they have a warranty of 7-10 years for the structural component of their houses. 20.5% claimed they have 5-7 years while 11.6% is between 2-5 years. For the participants that claimed that they do not have any warranty for their houses’ structural components was 7.5%. Only 86% of the participants managed to fill the questions while the remaining did not know the warranty for homes.

4.3.2 Warranties Offered for House owners on Minor Defects

It is noted that 86% of the participants took part in this question. From the results, 32% of the participants were offered 9-12 months warranties by house developers for any small repairs. A warranty for over two years was indicated by 22.8%. For the warranty of 3-6 months for minor defects, it was indicated by 12.1% of the participants. For 1-3 months warranty, it was indicated by 16.7% of the respondents. For a warranty for 6-9 months, it was indicated by only 2.3% of those who took part in the research. The results presented some variability which indicated the inadequacy of standard time frame for a warranty on rectification of defects that was observed by homeowners.

Table 3: Distribution of the provided warranty

4.3.3 Defects Observed by Participants

The researcher offered a 43 standard checklist of common defects in residential houses. The participants were allowed to add more defects to the list based on what they have observed. Those who responded to the question were 81% of the participants. 19% claimed that their houses were free from defects when it was handed over. It is noted that 42 defects were reported by the participants with additional of 13 defects identified as shown in the table below.

Table 4: Standard list of defects from the participants

Table 5: Additional defects noticed by participants

It is noted that defects under the rails category were not identified. From the results, the order of the ten most common defects included uneven painting surfaces, poor finishes, nail pops, poor flooring, windows and doors that are poorly fixed, kitchen units poorly installed, building cracks, poorly fixed locks, concreting and toilets. The number of defects had to be compered between each participant’s house. One participant claimed to have all the 43 defects in his house. The homeowner used a questionnaire to enclose the defects list to support the fact that there was an unsatisfactory quality performance from the housing developer.

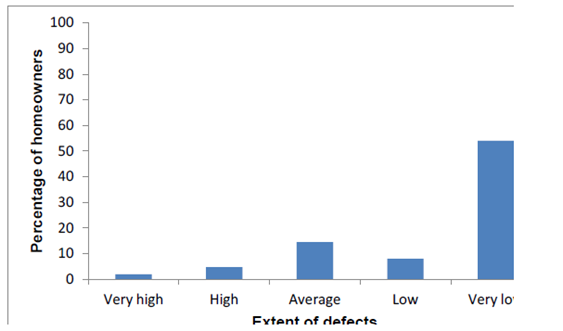

4.3.4 Extent of Defects

The research participants had to indicate on a Likert scale of five-point whereby one is very high and five is very low about the extent of defects identified in their homes. 82% of the participants gave responses, while 17% never responded because they had no defects in their houses.

Figure 3: Extent of defects distribution in percentage

The results showed that 62% of participants identified low defects levels in their houses, with 6.5% claiming to observe high defects. The average levels of defects were revealed by 14.4% of the participants. It was noted that 83% of the participants observed some defects that required rectification.

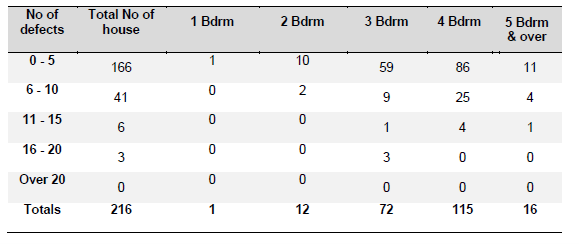

4.3.5 Defects Distribution across 216 Buildings

The defects were arranged into four categories, which are 0-5, 6-10, 11-15 and 16-20. It is noted that the number of defects was directly proportional to total bedrooms in a home. This implied that an increase in the number of bedrooms in the house had a rise in the number of defects. However, the relation was excluded from the five-bedroom houses, which had a relatively small number of defects.

Figure 4: Distribution of defects according to the number of bedrooms.

It was expected that there was there would be increased quality achievement with a decrease in several defects, but the extent of such an increase was not projected. Such results supported findings by a scholar that there is a big connection between the number of bedrooms and defects.

Table 6: Defects distribution within 216 buildings

From the table above, from the 166 houses surveyed, they had 0-5 defects while 41 houses had 6-10 defects. This implied that 77% of the houses were found to have 0-5 defects. There was an average of 5 defects per house and the maximum being 19 defects.

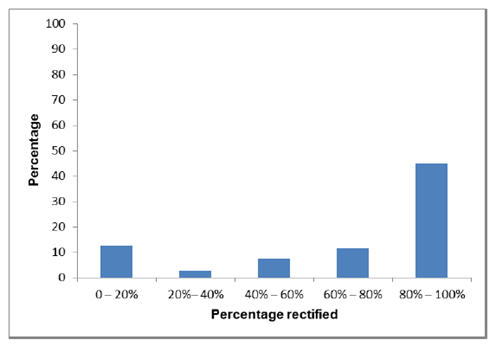

4.3.6 Percentage of Rectified Defects

Participants had to specify the percentage of defects that were rectified in their homes after notifying the developers. 79% of participants took part in this question. 45% of the participants suggested that 80-100% of the defects were renovated. 12% claimed that less than 20% of the observed defects were rectified while 60-80% rectification was observed by 11%. 40-60% rectification was observed by 7% and 3% claimed rectification of 20-40%.

Figure 5: Percentage of rectified defects

SECTION C

4.4 Homeowner Satisfaction

Participants had to denote their satisfaction level based on their home qualities and the services offered by house developers. The table below illustrated a summary of homeowner satisfaction responses.

Table 7: Homeowner satisfaction

Based on a scale of 1-7, participants had to rate their levels of satisfaction with one as ‘very satisfied’ and five as ‘very dissatisfied.’ There was a 99% response rate on this question. 64% of the participants claimed to be very satisfied with their home quality. 23% were moderately satisfied and 3% suggested that they had no response. Another 3.3% claimed they were slightly dissatisfied and 2.8% were neutral on the quality of their homes. From the results, a bigger percentage of homeowners were satisfied with their home qualities. This supported the results on the extent of defects as many homeowners claimed to have observed a low level of defects (Wong et al. 2017).

There was also a question on the level of satisfaction that homeowners receive from the services of developers. From the results, 53% of the participants claimed to be very satisfied with the services offered, while 25% were moderately satisfied and 4% of the participants were slightly satisfied. 4.8% were very dissatisfied, 3.8% were moderately dissatisfied and 25 being slightly dissatisfied with services from the developers. When examining the dissatisfaction end scale, 11.2% of homeowners were dissatisfied. This implied that 1 out of 10 homeowners is dissatisfied with the developer’s services.

CHAPTER 5: CONCLUSION & RECOMMENDATION

5.1 Conclusion

While maintenance of old buildings is a means through which one caters for historical preservation of a building and that of the community in general, it is an activity that can build up to disastrous consequences in the long run if not performed clearly. In Hong Kong, it is the legal liability and necessity to maintain the old buildings by the owners was very low. The owners habitually developed the attitude of waiting until there were many problems. Building defects crop up as a result of design errors, manufacturing flaws, use of substandard construction materials, or inappropriate use and fixing of materials to the structure, and largely the maintenance of buildings over the lifespan. It is, therefore, important that buildings receive proper inspection and maintenance to allow that members benefit from the safe and healthy conditions and that both property and lives of the building’s occupants are secured.

This research managed to identify the common contributors and the degree of attention of defects in buildings in Hong Kong. Building dilapidation remains a great problem in Hong Kong, one which needs to be resolved immediately if occupants and property managers are to enjoy the increased performance from the buildings. Various building defects exist in aged buildings. Of these, the most common remains structural defects which have resulted in cracks or collapse of the whole or part of the building; defective electrical wiring or lighting, defective or faulty plumbing and inadequate or defective drainage systems. The defects may also be as a result of damage by land movement or earth settlement. The act of building maintenance is a key aspect which is reviewed during the early stages of design construction to improve the quality of the building. For the aged buildings in Hong Kong, building maintenance needs to follow some objectives like replacements, repairs, renewals, protection, modification, decoration to safeguard the building’s internal surfaces and to clean.

This study focused on homeowners and building developers in Hong Kong as the main sample frame. This is because house developers are key when examining the issues or defects in aged buildings. The homeowners are vital when reviewing customer satisfaction levels. The results presented some variability which indicated the inadequacy of standard time frame for the warranty on rectification of defects that was observed by homeowners. It is noted that 42 defects were reported by the participants with additional of 13 defects. The order of the ten most common defects included uneven painting surfaces, poor finishes, nail pops, poor flooring, windows and doors that are poorly fixed, kitchen units poorly installed, building cracks, poorly fixed locks, concreting and toilets. A bigger percentage of homeowners were satisfied with their home qualities. This supported the results on the extent of defects as many homeowners claimed to have observed a low level of defects.

5.2 Recommendations

It is necessary to improve the level of quality monitoring systems in aged residential; buildings in Hong Kong. This would result in effective and efficient defects monitoring during the process of building production. A comprehensive monitoring system would enable homeowners to have better resources to examine the issues of defects in terms of how they can be rectified, the responsible person and the expectations (Sing et al. 2019). An effective quality monitoring will enable house developers to positively impact the level of satisfaction of their tenants. It is recommended that the Housing Authority develop a standard operating procedure (SOP) to enhance quality attainment. Such SOPs will be managed within all organizations of housing developers in Hong Kong.

The creation of a non-profit independent distribution National House Rectification Council is vital. The organization will help in raising the standards of aged buildings in Hong Kong and ensure there is full homeowners’ protection within such buildings. Standards which as highly severe will enhance best practice in the building industry and develop a culture to renovate and meet standards required for aged buildings. Such an organization will boost the confidence of house owners and improve their levels of satisfaction based on services and quality of their houses.

There is a need to have an independent building inspector that is mandatory for aged buildings. This will help the house developers understand the benefits that they can obtain from inspections that seek to improve their buildings standards(Subcommittee on Land Notice, 2010). The building inspectors have the technical knowledge to note visible and hidden defects which will call for the process of rectification before devastating effects arise. The independent building inspection will be part of the pre-purchase deal which will make house developers responsible for rectification of defects within a specified time frame.

The MBIS and the CBRE should be responsible for carrying out renovations on buildings in Hong Kong (Wong et al. 2017). A full renovation allows the building to achieve set regulations and building codes at the same time boosting the building’s value. Renovation of old buildings also improves the capital value and fit-out of the property, as well as advancing the value of the building to the surrounding. Dilapidated buildings have less modern and safety compliance. Renovation is especially mandatory according to the MBIS since older buildings are less likely to meet the mandatory minimum inspection requirements upon inspection, as most of the buildings were built decades ago (Lau & Ho, 2010). Nevertheless, people in Hong Kong are starting to develop an awareness of issues that are associated with poor building upkeep and are opening up to maintenance and renovation. Restoration and renovation is now a full-time career in Hong Kong, with the industry being worth millions, according to Wong (2017).