Pike River Coal Mine (PRCM) Accident Mediation Report

Individual Research Report in New Zealand Mining Industry

Workplace Health, Safety and Conflict Management

PIKE RIVER MEDIATION REPORT

Introduction

Workers of a firm have the most direct interest in workplace health and safety procedures. Effective participation of the workers in the organizational process can be ensured with the effective strategy of the Occupational Health and Safety (OHS) regulations process. Mining is an industry where the strict implementation of the OHS guidelines has been required. In New Zealand, the need for OHS is an important aspect as the mining industry of New Zealand has encountered numerous accidents. Report of Stuff.co.nz. (2010) has stated that starting from 1879, the Kaitangata Mine accident, New Zealand has encountered five mine accidents till the Pike River Coal Mine (PRCM) Accident. Several organizational and managerial issues resulted in the PRCM accident, which has been selected to analyze in the present report. Technological mismanagement along with the organizational policies both have an equal impact to cause the accident, and the report has selected to discuss all those aspects. Connecting the conflict resolution process, the present report has an aim to suggest the possible conflict resolution process to represent the possible ways for the solution of the selected problem.

Identification of Issues

Managing risk at the workplace as per health, safety standards have been significant for any organization. According to Samimi. (2020), the risk management procedure has been considered as the way by which identification, accessing, and controlling of threats or issues for an organization’s capital and earnings gets managed. On the contrary, risk management has been important for organizations as, without it, the form cannot possibly define its objectives for the future. Comprehending the PRCM catastrophe, there have been certain specified challenges related to the Occupational Health and Safety standards of the employees.

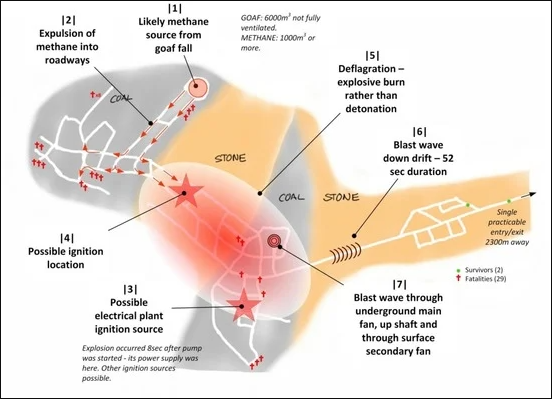

Image 1: Mining Location at PCRM

(Source: Pons, 2016)

- Geological conditions

It has been observed that the Pike River coal mine, which is located 46 kilometers NNE of grey mouth on the West coast of South Island New Zealand, has got a surface installation that reflects the environmental sensitivity of the place (Pons, 2016). Apart from that, it has been recognized that the surface condition was completely different from underground as the complex work of underground mining of that place had challenges mainly due to the unexpected geological condition.

- Issues in case of emergency

As stated by Perret et al. (2020), the underground mining procedure of coal itself is a hazardous and life-risking procedure. However, innovative solutions and execution of the procedure following certain guidelines mentioned by the consultants have always been helpful for Mining professionals to safeguard their life. The PRCM has installed the main fan underground near the upcast shaft, which suffered stability issues and would result in departure for the employees in case of any underground emergencies (Pikeriver. royal commission.govt.nz., 2021). On the other hand, entry and the exit point for the mining location were only through a 3km drift that was very dangerous.

- Issues relating to gas emissions and electrical equipment

It has been observed that gas emissions have been a vital challenge during any undermining procedures. Nevertheless, in PRCM, the gas has not been observed as a potential hazard which was a critical issue. Furthermore, The electrical equipment used for underground mining but not designed in a systematic manner that would help the miners combat any mine explosion.

Framing of Pike River areas of concern before the explosion

Although the Pike River coal mining area has been successfully presenting itself according to the environmental sensitivity and has also won the environmental protection award for its upgraded design and implementation. There have been multiple issues and challenges that have led to the PRCM disaster. The few areas of concern that are to be considered and indicate the risk-related challenges for the workplace environment are as follows.

- Ineffective managers looking after the mine

Although it has been observed that the board of directors for the mind have taken safety measures for health and safety management, in contrast, it has been taken into account that the safety manager and the safety committee at the mine both were unproductive. This has, in turn, made it impossible to estimate any issues that would have occurred in the future.

- Lack of action plan

Accordingly, it has been observed that gas concentrations within the explosive range have been detected many times. However, the life of action plans and irresponsible behavior of the managers within the mine has led to the severe problem and challenges of explosion in the PRCM. Moreover, it has been recognized that several safety issues have been highlighted. Nevertheless, no managers of the mine have taken the fact seriously and raised any safety matters.

- Management challenges

The scenarios have successfully presented that due to unprofessional management and experienced staff and workers in charge of the underground conditions, the issues have increased rapidly (BBC.com. 2012). Nevertheless, it could be stated that the second largest mine in the country would have securities and concerns for the miners and the members of the production firm. Therefore, it was rather unfortunate that the inefficient managers and the workers have been the major reason for the explosion in the PRCM.

- Avarice for manufacturing

The PRCM has not been a completed framework and was not a suitable structure for mining. According to an online review, the avarice for manufacturing compelled the employees to start work in that completed structure which was not at all ready for mining (nzhistory.govt.NZ, 2021). The ventilation procedure and the other infrastructures and electrical equipment required for mining were not updated and had encountered several criticisms from experts. This was also counted to be one of the reasons for the explosion in the PRCM.

- Poor Regulatory enforcement

The poor regulatory enforcement and the computation of high workload, and the lesser number of qualified workers have been responsible for the explosion that has occurred, killing several miners in the PRCM. Moreover, the defiance of the regulatory facts imposed by the government has also been another issue that has resulted in a severe explosion.

Site Risk Assessment and Hazard control

The explosion at the Pike River coal mine has been experienced due to certain conditions that the mine has been going through. There were several risk analyses that were done by the experts, and alerts were raised that were not taken care of by the managers and the employees in charge of the coal mine. First of all, it has been considered a serious matter of fact that the mind was not in the condition where the progress of work could be made. Nevertheless, it is greed for production that has compelled the employees to start working in that condition. Before the explosion, it has been observed that Pike has inherited several imperfect steps, which resulted in the adverse effect as an end result of the steps taken.

Lack of knowledge and skilled workforce

As per Cohen and Nadir. (2020), mining procedures have been regarded as a complex process that can be life-risking if not taken care of responsibly. Strategic planning of the health and safety measurement has been required for mining industries to execute the workforce environment procedures. However, the safety and health measurements in the Pike River were in a large draft form which was rather an issue for the management team to go through with patience. The working individuals and managers of the PRCM have not been efficient enough to go through the draft and manage the whole thing accordingly. The technical imports could be executed by other managers due to a lack of confidence and proficiency. It has been observed that the technical execution at the mining site was very lengthy and could not be implemented successfully. Nevertheless, it has been observed as one of the immature steps that have resulted in the explosion.

Frequent change in the management

First of all, the management of the Pike River mining has not been efficient enough to provide the best service dedicatedly and execute the work of mining. The company has frequently been changing its management in a short period of time that has made the work of mining inappropriate. Before the incident of the explosion, it has been observed that the chief management position has been changing six times in a period of 6 months. The frequent change in the management of the organization has dwindled the stability of the workplace and has affected the execution of work rapidly. The rapid change in the chief management positions has been adversely affecting the workforce planning, and the execution of the plan has been difficult for the employees as it has been rapidly changing with the change in the post. There have been few alerts that were estimated by the experts to be taken care of by the management team, like the up-gradation of the fan in the shaft, the drainage system, the entry, and exit position, the electronic machinery (Gunningham. 2008). The frequent change in the management position has not made all the alerts implemented and executed accordingly to maintain the health and safety of the employees. The results of the explosion have killed 29 lives due to the immature steps taken by different managers. Moreover, it has been taken into consideration that the greed for increased production has put less attention on the alerts identified by the experts. The frequent change in the organization’s management has also ignored the government regulations laid for safety and measurements.

Dependency over the contract procedure

It is a matter of the fact that every aspect of the mining has been regulated with reliance over the contracting procedure. The dependency over the procedures is intervened by the subcontractors (Gunningham. 2008). Nevertheless, the subcontractors focus on leveraging their profits and focus on the common construction workers for the mining procedures as they are unknown of the organisation’s health security guidelines in the mining industry. As stated by Pons. (2016), underground mining requires special training and knowledge of the OHS guidelines that help in the maintenance of peace and harmony within the workplace environment. It has been observed that the subcontractors and the employees recruited for the ventilation management and transportation management when not suitable for their positions lack the effectiveness and efficacy of their work that has resulted in the PRCM disaster (Caputo et al., 2019).

Conflict Resolution Mechanism and Process

The conflict has arisen with the change in perspective and needs. Conflict resolution is a process to come to an agreement through discussion or any process to achieve understanding about each other’s perspectives or demands (Brighthubpm.com. 2021). Among the different processes of conflict management, the understanding of each other’s perspective or demand can be solved through the discussion with the presence of another individual who can guide the process of discussion. Exploration of the possible solution and the understanding of the issues can be performed easily with the presence of an individual, who has the capability to make everyone understand the situation and the perspective of each other (Brighthubpm.com. 2021). In the workplace, the employer and employee relationship is an important aspect, where the employee’s claim has created pressure on the employer (Mediate.com. 2015). Under the condition of employee claim to the employer, a situation of mutual concern has been created, and things can be processed to the Employment Relations Authority or ERA as per the directions of the legal governance of New Zealand (Viamediationcentre.org. 2021). Instead of going to the court, the mutual demand and perspective can be evaluated through the process of discussion with the presence of an arbitrator, and that process of discussion can be termed as the mediation process.

Mediation process

There are different forms of the conflict resolution process, among which the meditation process has good applicability to the case of the PRCM accident as it has a relation with the informal and improvisational feel. Identification of the issues and goals for the agreement is an important aspect of the medication process (Tallodi, 2019). The Pike river incident has some prevailing issues to the mining situation, and the execution of mining has been commenced at a premature state of completion. Ventilation is an important aspect of OHS related to the mining process, and in the case of PRCM, ventilation management has misplaced and resulted in the system failure of the ventilation process (Mediate.com. 2015). In the mediation process, for the conflict management between the Pike River and employees related to the OHS guidelines implementation, the Council of Trade Unions or CTU would be selecting the arbitrator. Tallodi (2019), Opened Section 150 of the Employment Relation Act or ERA, has specified that the decision of the arbitrator should be respected by both parties during the conflict resolution process. A stable agreement could be concluded with the process of meditation if it had been applied in the PRCM case before the accident.

Who is involved in the mediation?

Employees of Pike river and the administrative team, managerial bodies would be involved as the two parties for the medication process. In the observed situation, the management of the Pike River has an approach to leverage the product without making the process of OHS management efficient (Mayer, 1987). Instead of looking for an action plan for improvement, the organization has a focus on leveraging the production process (Tallodi, 2019). In such cases, the conflict between the Pike River and the employees could be managed with the meditation process, where the employee would be able to represent the demands and needs.

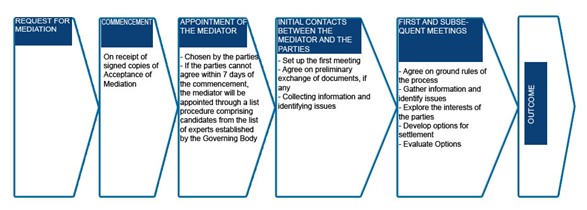

Figure 2 Different Steps of Mediation process

(Source: Tallodi, 2019)

Describe the mediation: Steps in the process

Meditation is a process that is relevant to the significant number of steps and stages related to conflict management. The steps related to conflict management through the mediation process are- (a) Planning for meditation through the initial discussion and (b) introduction of a mediator for (c) opening remarks for the conflict resolution process. Opening remarks have opened a space for the (d) joint discussion and (e) caucuses and (f) negotiations (Tallodi, 2019).

Analyzing the risks and security concerns at the mine, Pike River can ask for the meditation process and apply to the CTU as well as Pike River had an option to lodge the request for meditation at Citizens Advice Bureau (CAB) under the Ministry of Business, Innovation and Employment (MBIE) guidelines (stuff.co.nz. 2010). MBIE has an option to receive the request for mediation through Phone calls or through email. But the participating bodies should have enough proficiency in the technical processes. The issues of lack of regulatory enforcement and Avarie for manufacturing could be identified as the major issues for the conflict (nzherald.co.nz. 2021). The consequences for the regulatory enforcement have caused an issue of ventilation mismanagement and the hydro-mining process. The meditation regarding the transparent enforcement of the management operation can be mediated.

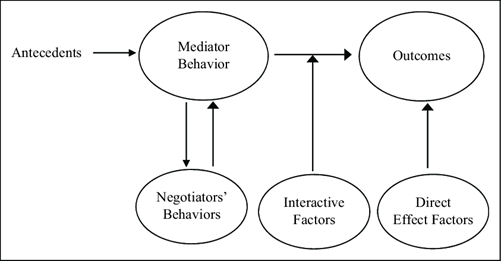

Figure 3 Negotiation process

(Source: Mediate.com. 2015)

Non-negotiables, negotiables, and things to give away

Non-Negotiables: Lack of action has been reflected in the ineffective management planning for the mining process. Ineffective managers chasing for mine; as a result, the compliance to the OHS guidelines has been impacted (theguardian.com. 2020). Pike River would chase after the mining and leverage the production process. It could be the most probable non-negotiable element. The attempt of Pike River for production maximization could not be an option for the negotiation.

Negotiables: methane emissions and lack of proper management of the electrical equipment have created safety concerns at the mine (Mediate.com. 2015). It is the most prominent concern for the employees working in the mining industry. The situation of gas leakage and faulty equipment has created an issue for emergency situation management (nzherald.co.nz. 2021). The identified issues would be more prominent in the case of PRCM as the underground mining process has been employed in the mountainous area. Hence, the most important negotiable is the proper management of electrical equipment and controlling of the methane in the mine (Parliament.nz. 2012).

Give Away: lack of action could not be enough option to come into the negotiation with the party. The management process and idea for action have been dependent on the organization. It should be taken as the give-away option for the mediation process in this case (theguardian.com. 2020). Above all, the mining industry is the most sensitive industry, where strategic planning has been required for occupational health and safety concerns. Hence, the consideration of the give-away related to this process should not be taken into the mediation process.

What is the most important, and what will happen if this is not ‘given’?

Among all the negotiations and considerations, the major issue has been related to the mismanagement of the electrical equipment and the leakage of gas in the mine. Electrical equipment in the case of underground mining is a sensitive element as it might cause fire at the mine (Shabudin et al., 2017). In coal mining, the electric short circuit and issues with the electrical equipment are very dangerous (stuff.co.nz. 2010). Ineffective management of the electrical equipment could be more severe in the presence of gas leakage. Methane gas is highly inflammable, and an electrical short circuit could be of severe form in the presence of the Methane gas (Parliament.nz. 2012).

If this important negotiation for the improvement of electrical equipment to combat the electrical short circuit was ignored, then the situation could be difficult, and an explosion would be a certain result (stuff.co.nz. 2010). The reaction of methane with the leakage current from the equipment would create a flame of fire within the mine. Hence, the issue should be taken with prime importance.

What is agreed to and timeframes?

It would be agreed with the mediation process that the management would take the initiative for the improvement of the electrical equipment as well as the improvement of the situation of the employees (theguardian.com. 2020). Training for the employees would be an effective step of the agreement, where the employee would be able to understand the different issues related to the workplace and act as per the requirement of the situation (Rasmussen & Suedung, 2000). The mining process has been executed before the completion of the full structure of the mine. The conflict resolution would be agreed upon for the completion of the mine structure and the testing of the mining environment before the further execution of the mining process (Shabudin et al., 2017).

The mining process would be stopped immediately after receiving the report of non-compliance to the guidelines of OHS. Within one month after receiving the notice, the process for training and repair of the electrical equipment would be started. The time allotted for the whole process would be 6 Months.

Negotiables

The stability of the management process and adherence to the guidelines of OHS has been required to be followed in the mining execution process. The major negotiables for the mining process would be-

- Moving from the dependency of the Contractual workers for the mining process, the full-time employment for mining under the Pike River could be negotiated. This would help the organization in getting a permanent and skilled staff for the mining, who have the understanding regarding the OHS guidelines (Rasmussen & Suedung, 2000). The training could be offered to those employees for improved performance.

- The level of methane in the air of mine has increased the potential of the risks of accidents and disasters. In such cases, the regular tracking of the methane level in the air of mine could be an effective step for the health and safety standard measurement in the mine (Lamm & Lips-Wiersma, 2018).

- The hydro mining process has been performed with risk assessment for this process. The risk assessment of the hydro mining and the analysis of the structure of the Hydro cross-cut has been required for the separation of the intake air and expelled air (Lamm & Lips-Wiersma, 2018). The hydro mining process could be improved with the separation of the improvement of the ventilation process. Based on this issue, improvement of the ventilation process with the exact placement of the fans could improve the hydro mining process and minimizes the risk (Mayer, 1987).

Conclusion

The lack of improvement approach of the management team has resulted in the improper maintenance of the ventilators. Even after a certain period of time, when the projected production limit did not match with the actual production volume, the company has cut down the expenditures for the OHS implementation. The Ignorance of the Pike River in the implementation of OHS guidelines has been alerted by the government several times. Immediately before the accident, Pike River was alerted by the government, but the employees of the firm have maintained silence against the PRCM regarding the response of the Pike River in turn of the governmental alert. Hence, the improvement of the ventilation process and development of workplace-oriented and health concerned managerial bases can be formed with the meditation process. Mediation as a part of conflict resolution would be effective to maintain the safety and health standard at PRCM.